In recent years, ceramic foam filters molten metal filtration have been developed as a new type of filter to reduce casting defects. Foam ceramics have the characteristics of lightweight, high mechanical strength, large specific surface area, and high porosity. The molten metal has excellent thermal shock resistance, chemical corrosion resistance, and high-temperature stability. With the distributed pore network structure, they can increase the surface area and absorb the sintered ore, the liquid metal becomes purer, and the waste quality problems such as sand holes and pores are much less. The casting quality becomes better.

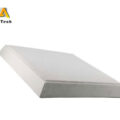

Ceramic foam filters molten metal filtration are an economical method for removing aluminum inclusions in aluminum melting and foundries. Due to the different conditions of use, the actual effect usually increases with the decrease of the filter plate hole size and the decrease of the flow rate of molten aluminum.

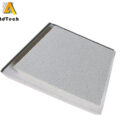

The molten metal ceramic foam filter is specially treated and is not easily damaged. The ceramic filter has high strength, excellent aluminum water erosion performance, and good thermal performance. It is an ideal choice for the production of various castings.

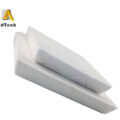

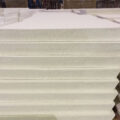

The manufacturing process of the metal foam filter is usually to squeeze the excess dry polyurethane sponge into the ceramic slurry, and finally fire at a high temperature to form a three-dimensional porous ceramic material with the relevant original bubble structure.

Considering the filtration efficiency and strength, the prepared ceramic foam filter is no longer a three-dimensional network structure. Instead, they are interconnected, twisted, and unevenly thick pipes. This uneven wall surface plays a key role in trapping small inclusions in the aluminum melt (ie, deep filtration). This is the fundamental difference between the screen and the ceramic foam filter used for casting. This three-dimensional network structure increases the flow path of the aluminum liquid, makes the aluminum liquid contact the filter plate, and increases the adsorption capacity of the inclusion particles.

In the initial stage, surface sieving intercepts large particles, while small particles are removed by a deep filtration mechanism. With the formation of surface deposits, the deposits can retain large and small particles. Smaller inclusion particles can be captured by a deep filtration mechanism. At this time, the filtering effect of the ceramic foam filter will be better.

When the particle adsorption reaches saturation, that is, the number of particles adsorbed from the melt is equal to when the particles are taken away by the melt flow, its slag removal ability decreases.