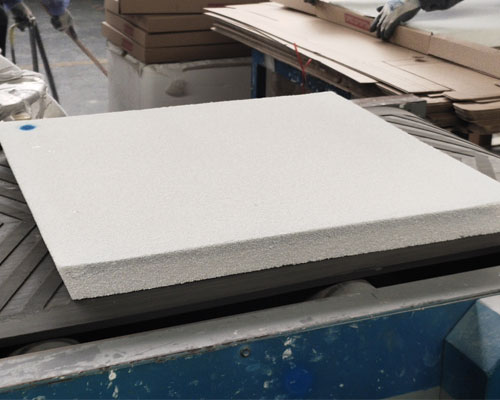

Ceramic foam filters are used to remove or reduce entrained solids from the final cast product, especially for molten aluminium, especially when the resulting metal is used in decorative products, for example as a decorative border made of 5000 series aluminum alloy Strips or plates, such as 5252 and 5657 aluminum alloys. Other aluminum alloys that benefit from improved filtration include aluminum capacitor foils made from 1000 series aluminum alloys, such as aluminum alloys 1145 and 1188. In order to reduce pinhole defects of light rail products and maximize rolling efficiency; high-strength extruded alloys, such as aluminum alloy 2024 and 7075, to obtain high ultrasonic quality; and 6000 series aluminum alloy extruded alloys, such as 6061 aluminum alloy, In order to obtain higher productivity in the extrusion operation; etc.

Molten metal, especially molten aluminum, often contains entrained solids, which are harmful to the final cast metal product. These entrained solids appear as inclusions in the final cast product after the molten metal is solidified, and cause the ductility of the final product to decrease or the smoothness and anodizing properties of the final product are poor. Inclusions may come from several sources. For example, inclusions may come from a surface oxide film that is broken and entrained in the resulting molten metal. In addition, inclusions may come from insoluble impurities, such as carbides, borides, etc., or corroded furnace and tank refractories.

The above-mentioned inclusions cause the performance loss of the final solidified alloy, and cause the reduction of processing efficiency and the performance loss of the final product. For example, one type of finish defect that is particularly important in decorative strips or plates made of aluminum alloy 5252 is a finer defect called a linear defect.

Strict melt processing technology minimizes the incidence of such defects. Conventionally, inclusions in the melt are filtered by the melt to reduce such defects. The most common form of melt filtration is to use an open woven glass cloth screen, which is placed in a transfer and casting tank or in a molten metal pool on top of a solidified ingot. It has been found that such filters are only partially effective because they only remove larger inclusions. Aluminum factories often use ceramic foam filters for molten aluminium, which are very advantageous in molten metal filtration, especially molten aluminum, and are conveniently prepared at a reasonable cost without polluting the melt.