The quality of Ceramic Foam Filter Volkhov Aluminum melt is very important. It is used to filter pollutants in molten aluminum. Therefore, countries all over the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution. On the one hand, during the melting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized, reacts with water vapor to absorb hydrogen, and easily forms various forms of non-meta slag.

On the other hand, part of the scrap in the combined charge contains some non-aluminum impurities during the recycling process. Because the waste comes from process waste from various processes in the factory and off-site waste, the route is different, the composition is complicated, and the quality is poor.

These impurities are easy to produce bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, and then affect the processing performance, mechanical properties, corrosion resistance and appearance quality of the product.

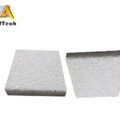

Ceramic Foam Filter for Aluminum is suitable for the production of high-quality aluminum materials and high-demand aluminum alloys. Through the purification process of physical adsorption and chemical erosion, it can effectively remove various oxide inclusions generated in the aluminum melting process, thereby reducing casting defects and improving casting quality and ensure high productivity.

Ceramic Foam Filter Volkhov Aluminum can effectively remove all kinds of small to micron-level water in aluminum water, and convert the aluminum water into a smooth laminar flow. It has good mechanical strength and chemical stability, and excellent ability to wash aluminum; strictly control the pore size and throughput to achieve stable filtration.

The ceramic foam filter is surrounded by a heat-expandable ceramic fiber sealing insert, which helps to seal the filter plate in the filter housing to prevent metal leakage.