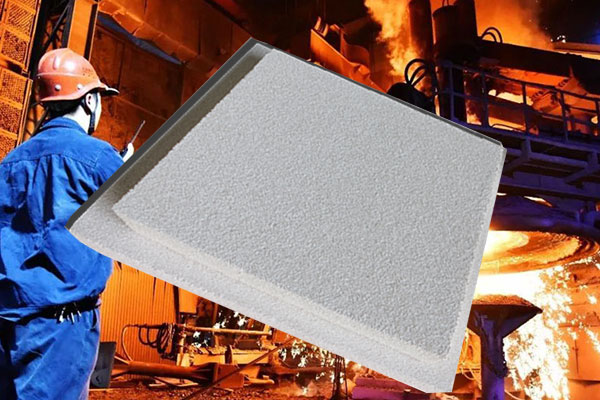

Ceramic Foam Filter Korba Aluminium is an important link in the process of aluminum alloy smelting, and is one of the alloying purification and refining treatment technologies in the process of aluminum alloy smelting.

It has long been an important means to remove non-metallic inclusions from aluminum alloy melt by means of in-furnace particle refiner treatment and foam-ceramic filtration.

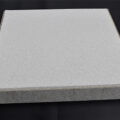

Foam ceramic filter plate is widely used in metallurgy, chemical industry, environmental protection, and other fields, with good chemical stability, high specific strength, high-temperature resistance, thermal shock resistance, large specific surface area, and many other advantages.

In aluminum alloy metallurgy, it is one of the effective ways to purify aluminum melt by using a foam ceramic filter plate to remove the heterogeneous impurities such as metal slag and inclusions.

The removal of slag can also reduce the amount of hydrogen in the aluminum melt.

Because of its good slag removal effect, simple operation, ease to match with other parts, low cost, the ceramic foam filter molten aluminum filtration processing has become a conventional means of purification.

With the higher and higher requirements on the quality of aluminum products, the higher and higher requirements on the filter plate.

Ceramic Foam Filter Korba Aluminium to remove impurities in metal melt, especially small inclusion particles, is indeed very effective. The structure and filtering mechanism of ceramic filter plate introduced here will help readers to evaluate the filter plate and choose and use the filter plate correctly. The recommended selection criteria for the use of filter plate can be used as a reference for beginners, and users can find a more reasonable selection and use the method according to the cleanliness degree of aluminum melt, the requirements for the final product and the accumulated experience in the use.

Foam filtration is the last process of aluminum melt purification. It is particularly important to select the second generation of foam filtration plate. In particular, it is necessary to prevent secondary contamination of aluminum melt from leaving the filter box until it solidifies. In this process, the flow tank, front box, distribution plate and hot cap made of molten quartz ceramics with long life, high strength, non-stick aluminum and good thermal insulation are adopted, and the possible pollution source is eliminated by timely dehumidification and cleaning, which can not be ignored to ensure the cleanliness of aluminum melt.