When these inclusions appear in the final cast product after the molten aluminum is solidified, they cause the final aluminum product to be less ductile or to have poor finishing characteristics. Therefore, it is important to remove entrained solids from the molten aluminum before it is cast into a solid body. In general, the ceramic foam filter for foundry is used for removing entrained solids from molten aluminum alloys before casting.

In the aluminum casting process, molten aluminum generally contains entrained solids, which are deleterious to the final cast metal product. These entrained solids usually derive from three sources. Some are particles of aluminum oxide, which are drawn into the liquid stream from the floating oxide layer on its surface. And some entrained particles are fragments of furnace lining, transfer trough and other portions of the molten aluminum handling equipment which are eroded and entrained in the flowing aluminum stream. And some particles are precipitates of insoluble impurities such as intermetallics, borides, carbides, or precipitates of other aluminum compounds, such as chlorides.

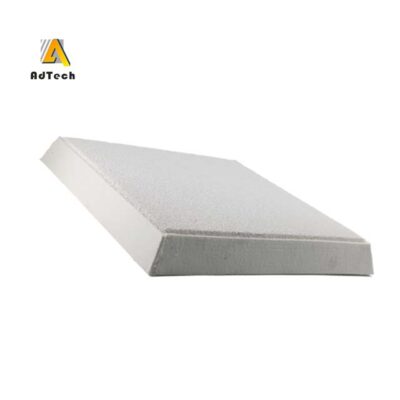

Ceramic Foam Filter for Foundry

Ceramic Foam Filter (CFF) can remove inclusions, which are generated between the refining system and the mold table. It is filtering by reducing the level of non-metallic inclusions and oxide films that are present in the molten metal. The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of metal. Accordingly, the quality and the productivity in downstream operations such as forging, extruding, and rolling are guaranteed.

In general, the methods filtering are used for removing entrained solids from molten aluminum alloys before casting.

Ceramic Foam Filters are used in producing high quality aluminium sheets, aluminium foils, and other castings. It can effectively remove inclusions from liquid aluminium by physical adsorption and chemical adsorption, for the purposes of eliminating the lacuna of casting, improves the quality of casting, provides superior material for further machining. Inclusions such as oxides can be removed using Ceramic Foam Filters. Ceramic Foam Filters are white or lactary white alveolate ceramic filter.

Ceramic Foam Filter

Ceramic Foam Filter is made from alumina, the ceramic foam filter maintains its high strength and its excellent resistance to chemical wear through the cast. The pore network within the filter provides a large surface area for inclusion entrapment. Filter dimensions range from 7, 15, 17, 23, 26 inches and pores size from 20 to 80 ppi. For high cleanliness requirements, double filters are available having two pore sizes.

Benefits

Particles larger than the pore size are captured at the top of the ceramic foam filter

Smaller particles are captured on the filter cake created by the larger particles

Finer particles are captured within the pores in the filter

Improves mechanical properties of castings

Increases process yield

Reduces porosity in the metal thus improving quality

Lengthens tool life in post foundry operations

Gives increased productivity

[…] used, the head is large before the aluminum melt passes through. After the melt passes through the alumina ceramic foam filter, the head is rapidly reduced, generally about 5mm. But with the use of the filter, the pores are […]

[…] Molten Aluminum Filtration Foam Ceramic Filter for Liquid Aluminum Aluminium Foam Ceramic Filters Ceramic Foam Filter for Foundry How to Install Porous Alumina Plate Ceramic Foam Filters for Sale Ceramic Foam Filter Aluminium […]