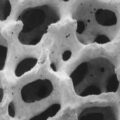

The ceramic foam filter has an excellent filtering effect for aluminum water. It uses a three-dimensional structure to effectively remove oxidized inclusions and other non-metallic inclusions by blocking, capturing, and adsorbing. After the molten aluminum is filtered, the product quality will get satisfactory results.

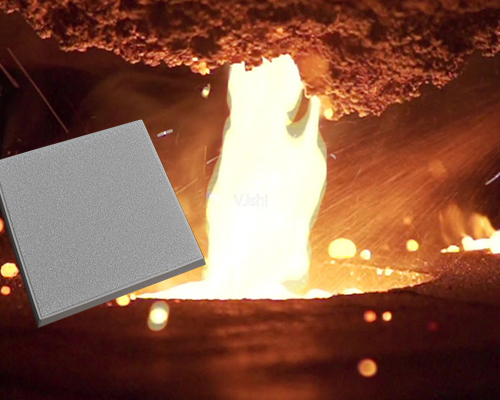

Aluminum products are widely used in areas that require high strength and elongation requirements. Therefore, cast aluminum is very sensitive to defects caused by impurities. Impurities are mainly composed of non-metallic particles, molten slag, and refractory fragments.

The alumina ceramic foam filter can effectively remove these impurities, improve the surface quality and mechanical properties of the castings, and reduce the rejection rate.

The alumina ceramic foam filter can fill the cavity more uniformly with molten metal, and the molten metal has a higher tendency of turbulent flow. After the three-dimensional pore structure of the ceramic foam filter, the turbulent flow is finally converted into a very stable laminar flow. Laminar flow can fill the cavity better, thereby reducing the impact corrosion of the metal solution on the casting cavity and significantly reducing the rejection rate.

Alumina foam ceramic filter, applicable temperature 1250℃, suitable for filtering and purifying aluminum water. In order to meet the increasing quality requirements of aluminum castings, the use of alumina ceramic foam filters is becoming more and more important.

The alumina foam ceramic filter product effectively removes the solid inclusions in the molten metal, so the aluminum alloy can be forged, aluminum foil manufacturing, extrusion processing and other processes smoothly, and perfect aluminum products can be obtained. The product has a selection range of 10ppi coarse pore size to 60ppi very fine pore size, and there will always be a product standard that suits your requirements. Both the ordinary size and the special size required by the customer can meet the requirements.