The CFF system uses special ceramic foam filters for casting, it can remove the inclusions generated between the refining system and the mold table. The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the metal solidification process. Therefore, the quality and productivity of downstream operations such as forging, extrusion and rolling are guaranteed.

At Adtech, the constant pursuit is to ensure that our customers have access to the best technology available on the market to produce the highest quality billets, slabs or ingots for their customers. Our guarantee will not stop at our customers, but will continue to our customers’ customers! Our technology ensures the consistency of casting quality for the most critical final product applications.

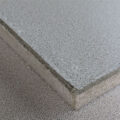

The ceramic foam filter uses high-quality foam and high-purity ceramics as raw materials, which can effectively remove the non-metal solid mixture of molten aluminum and aluminum alloy flux in the aluminum casting industry.

The ceramic foam filter for casting uses a three-dimensional network structure and organic bubbles connected to the pores as a carrier to invade the thixotropic alumina material slurry.

The ceramic foam filter adopts a square-corrected center-to-center automatic extrusion process to uniformly apply the slurry to the bubble skeleton of the carrier, and to bake and solidify at a high temperature of 1180°C.

The ceramic foam filter is installed in the filter box to filter aluminum alloy liquid impurities to meet the high added value and high-tech performance of aluminum alloy precision casting for aviation and transportation. Such as: computer hard disk, PS board base for printing, cans, jet turbine fan blades and other products. We are a professional manufacturer of ceramic foam filter plates for aluminum factories.

Advantages of Ceramic Filters for Casting

- Adopt the principle of adsorption to filter, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions;

- No slag, effectively reducing the pollution of molten aluminum;

- Good thermal shock resistance, improved corrosion resistance to molten metal;

- Automatic assembly line production, three calibration procedures, accurate size, more suitable for filter box use;

- Improve surface quality, improve product performance, and improve the effect of microstructure.