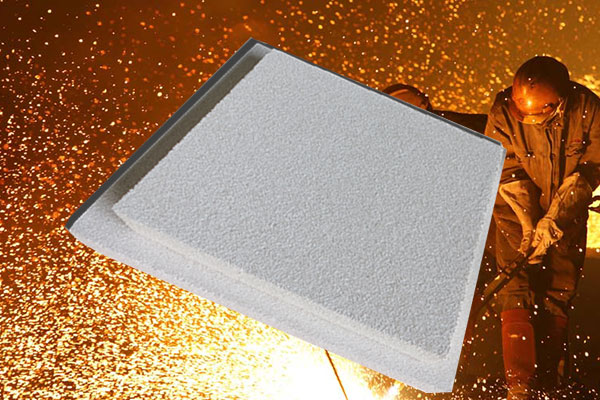

Ceramic Filter for Scrap Aluminium is one of the keys to the purification and filtration of aluminum scrap smelting process.

Ceramic Foam Filter can remove the non-metallic inclusions in the aluminum alloy melt. It is treated with flux in the furnace.

The ceramic foam filtration technology outside the furnace has become an important method for the purification of molten aluminum.

Ceramic Foam Filter Molten Metal Filtration is specially designed to produce high-quality cast products in aluminum casting workshops.

Ceramic Filter for Scrap Aluminium can reduce waste caused by impurities, reduce costs due to impurity defects, achieve faster extrusion or hot rolling speeds, increase productivity and easy replacement alloy. No need to retain metal to increase casting flexibility.

The domestic recycled and imported scrap aluminium has high impurity content, and most of it is remelted and manufactured into die-cast aluminum alloy. In 2019, my country’s recycled aluminum output was 7.15 million tons, of which the output of die-cast aluminum alloy was 5 million tons, about 70%, and deformed aluminum The output of alloy is 2.15 million tons, which is about 30%. Compared with wrought aluminum alloy, die-cast aluminum alloy has a lower aluminum content and allows more impurity elements, so most of the scrap aluminum is finally made into cast aluminum alloy. SMM statistics show that 80% of recycled aluminum is ultimately used as aluminum castings, 15% flows to aluminum rods, and the remaining 5% enters the strip and foil, that is, most of the old scrap aluminum is eventually degraded and used.

Although the recycling rate of waste cans in my country is close to 100%, many recycled aluminum cans are not used in the production of cans, but are downgraded for use in other aluminum processed products. The main reason is that the waste cans have coating materials, etc., and the surface organic matter is difficult to deal with. There are single-piece cans, two-piece cans, three-piece cans, etc. There are large differences in the chemical composition of various types of aluminum cans, which hinder the recycling of waste aluminum cans as raw materials for cans.