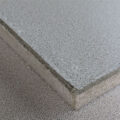

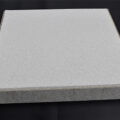

Ceramic Filter For Aluminium Rod prevents inclusion particles and their agglomerates whose size is larger than the pore size of the filter surface.

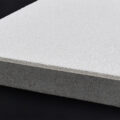

The performance requirements of aluminum and aluminum alloy products continue to improve, so new requirements are also put forward for aluminum liquid filtration.

The molten aluminum is required to have good casting characteristics such as high purity, fewer floating impurities, and smooth flow rate of the molten aluminum, so that the cast aluminum products have excellent physical and chemical properties and machining performance.

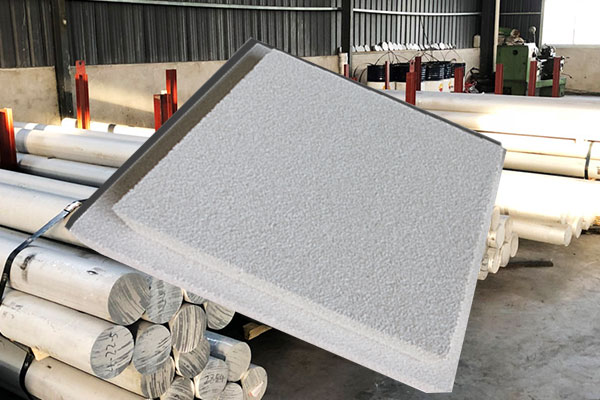

Ceramic Filter For Aluminium Rod is widely used in aluminum and its alloy casting industry. The ceramic foam filter is a combination of excellent strength, thermal properties and resistance to attack from molten aluminium.

Ceramic Foam Filter is the last process of aluminum melt purification treatment in the aluminium rod casting process. It needs to be specially pointed out that it is necessary to prevent the secondary pollution of the melt that may occur during the process of solidification and forming after the aluminum melt leaves the CFF filter box.

Aluminum rods are one of the largest types of aluminum processing intermediate products. Aluminum processing companies have begun to increase the ratio of scrap aluminum to replace primary aluminum. For example, in 2019, the production of remelted aluminum rods from scrap aluminum exceeded 1 million tons. SMM statistics show that in recent years, the market share of remelted aluminum rods using recycled aluminum has gradually increased. In 2019, the output of aluminum water rods accounted for 70%, and the remaining 30% was basically produced by recycled aluminum. Under the premise of not significantly affecting the alloy composition of aluminum rods, the use of scrap aluminum can significantly reduce the cost of raw materials for enterprises.

Primary aluminum and scrap aluminum have a certain degree of mutual substitution, but the substitution is restricted by factors such as economy, product composition requirements, and technological level. An important factor that affects the proportion of aluminum scrap added by enterprises is the price difference between primary aluminum and scrap aluminum. In the process of rising aluminum prices, the price increase of primary aluminum was greater than that of scrap aluminum, and the price difference of refined scrap widened; during the process of falling aluminum prices, the price of primary aluminum fell more than that of scrap aluminum, and the price difference of refined scrap narrowed. The greater the price difference of refined waste, the stronger the willingness of enterprises to increase the proportion of recycled aluminum, but the element content standards of aluminum alloy products must also be considered.