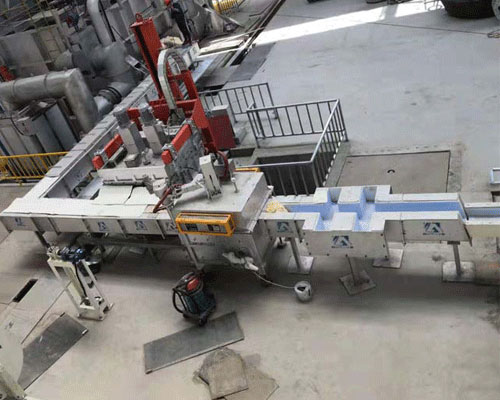

Metal Launder System for Molten Aluminum Conveying is one of the basic equipment for aluminum alloy casting, it can ensure metal quality. The main function of Casting launder is to divert the aluminum liquid from the furnace to the casting machine. The working area was originally built using a flow tank for the traditional high-temperature […]

Ceramic Launder

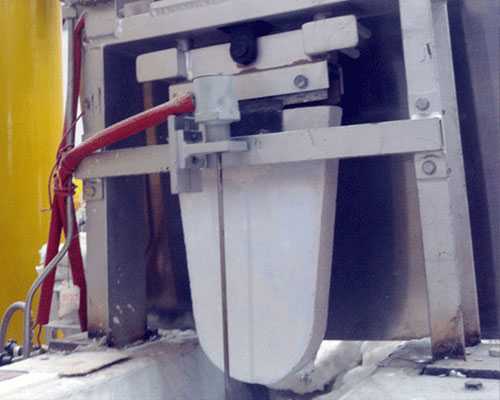

The Aluminum Casting Launder is a key component in a large aluminum alloy casting production line. This is the channel to ensure that the high-temperature aluminum liquid smoothly enters the pressure chamber. A smooth transfer is a key to improving the quality of the melt, because any turbulence will cause oxides in the molten aluminum. […]

Refractory Trough is one of the basic equipment for aluminum alloy casting. The main function of the aluminum casting launder is to drain the aluminum liquid in the mixing furnace to the casting machine. The operation area was originally made of traditional high-temperature resistant castable masonry. The surface of this type of groove is easy […]

In the casting of light metals, aluminum, and aluminum alloys, it has been a common practice to melt the metal in open hearth or other type melting furnaces that are heated by the burning of conventional fuels. In preparing the metal for casting, the charges of metal and desired alloying constituents are generally added to […]

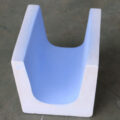

A trough is used for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body is embedded in the insulating layer. At least one heating element is positioned […]

A particular type of trough and launder has a channel for directing a stream of molten metal to flow from a furnace to a mold. Such a trough, which is known as a launder, is typically formed in sections that are connected end-to-end. The launder may have a cover over the channel, and may include […]

The flow trough is provided with a baffle system, the baffle system is laterally arranged on the launder and trough, so as to promote the static flow of the fluid circulating around the flow trough, thereby facilitating the sedimentation of the particulate filter medium from the fluid. The flow trough is also provided with an […]

The launder transfer system is designed to transfer and deliver of molten metal from a melting furnace. It can smoothly transfer the metal up and out of the furnace using the flow of a gentle vortex. An integrated light weight launder system delivers this flowing metal for use by the downstream process. The system generates […]

AdTech supplies a launder for the conveyance of molten metal. The metal flows in the lower part of the launder construction in a channel defined by a refractory mass, the launder being heat-insulated so that, in operating conditions, the metal forms a solid zone in the porous refractory mass. The essential features of the ceramic […]

A launder is used for molten aluminum casting has a steel jacket and which is lined with refractory material, is provided with an insulating cover. The extra heating of the launder is implemented by a gas burner. A discharge system for the gases from the launder is arranged in the launder cover. The cover of […]

Contact Us

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com

About Us

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

Address

NO.39 GARDEN ROAD, JINSHUI DISTRICT

ZHENGZHOU, HENAN, CHINA

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com