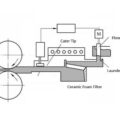

The casting nozzle and tip are a key component that directly distributes and transports the molten aluminum to the roll gap during the casting and rolling process. The rationality and practicality of its structure and the selection of nozzle materials are very important for normal production, stabilizing various process parameters and improving the quality of cast-rolled slabs.

Caster nozzles and tips often explode due to gas accumulation in the nozzle cavity during casting and rolling production. By punching holes from the surface of the nozzle plate and using far-infrared nozzle baking technology, the possibility of gas accumulation in the nozzle cavity of hard materials can be greatly reduced.

The special process of casting nozzle material can effectively prevent molten aluminum from corroding the casting nozzle and avoid carbonization. Fracture tissue is a fine and uniform layered fiber structure that can prevent the existence of flocculated tissue. The coating on the working surface is uniform and smooth to prevent particle cracks and coating shedding, and to provide protection for high-quality cast-rolled plates.

The casting nozzle and tip are an important part of the aluminum strip continuous casting and rolling mill, and its quality directly affects the quality and output of the aluminum strip continuous casting. Casting tip is used for the crystal formation and size control of aluminum plates, strips and foil billets in casting and rolling production lines. It is formed by vacuum suction filtration of high-purity fibrous materials, and processed by sophisticated equipment.

The casting nozzle plate splitter assembly is assembled with the nozzle plate to adjust the uniformity of the internal flow, reduce the temperature error of the internal molten metal, and effectively protect the internal structure of the cast-rolled coil during the casting and rolling production process. The castertips use effect with boron nitride coating is better.