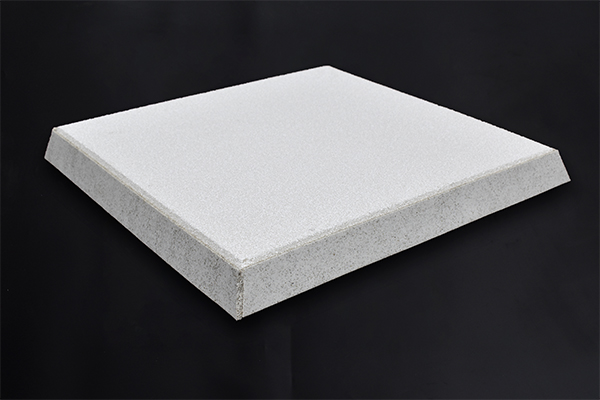

Casthouse Filter is the most effective way to remove inclusions from aluminium melts. Ceramic foam filters have a multi-layer network, multi-dimensional through-holes, and the pores are interconnected.

When the molten metal is filtered, the molten aluminum carries the inclusions along the tortuous channels and pores, contacts with the foamed skeleton of the CFF filter plate, and is directly retained, adsorbed and deposited. When the melt flows in the hole, the channel of the filter plate is bent, the melt flowing through the channel changes the flow direction, and the inclusions collide with the hole wall anvil and adhere firmly to the hole wall.

Some inclusions in aluminum alloys come directly from the charge, while most of them are formed during smelting and pouring, mainly oxide inclusions. Casthouse Filter is used in melting process and refining process of aluminium scrap.

There are generally two methods for scrap aluminum smelting

1. Smelt aluminum scraps into ingots (recycled ingots), and stack them according to their chemical composition.

2. During smelting, the recycled steel ingots are mixed into the furnace to smelt the finished product.

Analysis and Prevention of Melting Defects

Causes of pinhole defects in aluminum alloys

1. The charge and smelting tools are not completely baked.

2. The melting temperature is too high or the melting time is too long.

3. The aluminum liquid stays for too long after deterioration.

4. The alloy refining is not good.

5. The workplace is too humid.

Precaution

1. Charges and tools should be thoroughly dried.

2. Control the melting temperature, generally not exceeding 7400C, not exceeding the pouring temperature, and also prevent local overheating of the alloy during the melting process.

3. The operation is fast and the melting time is shortened as much as possible.

4. Be careful in refining operation, refining is the best way to prevent blowholes.

5. After modification, the alloy liquid should be poured for 8-15 minutes in time.

6. Keep the smelting site dry.