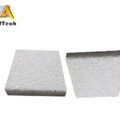

Cast ceramic foam filter is an effective molten metal filter. Its three-dimensional connected network structure and high porosity have many advantages, such as large area slag collection. The inner surface has a large filtering area. The ceramic foam filter is one of the sizes with small flow resistance and good filtering effect, and the size can be customized.

The wheels, steering knuckles, cylinder pistons, cylinder heads, aluminum ingots, aluminum materials and other precision casting aluminum alloy parts of automobiles and motorcycles are all made of aluminum alloy. Molten aluminum contains a certain amount of slag during the casting process, and the molten aluminum contacts air. It is easily oxidized and produces impurities such as oxide scale.

Some of the inclusions in aluminum alloy come directly from scrap, most of which are formed during the melting and casting process, mainly oxide inclusions.

Inclusions and gases in the metal will seriously affect the strength, fatigue resistance, corrosion resistance and stress corrosion cracking performance of the material.

The amount of inclusions in molten aluminum has an important influence on the quality of aluminum and aluminum alloy ingots. In order to improve the purity of molten aluminum, filtration is usually used in the production process of aluminum and aluminum alloy ingots to remove non-metallic inclusions in the melt.

The actual filtration capacity of cast molten metal filter production depends on the on-site casting conditions (alloy, temperature, number of inclusions, etc.).

At present, filtration methods mainly include glass cloth filtration, deep bed filtration, ceramic tube filtration and foam ceramic filter plate filtration. Foam ceramic filter plates are widely used due to their convenience, low cost and high filtration efficiency. It has become the first choice for filtering molten aluminum.

As the quality requirements of ingots increase, the requirements for the purity of molten aluminum during the casting process are also getting higher and higher. Therefore, when ceramic foam filter plates are used to filter molten aluminum, the pore size of the filter plates becomes smaller and smaller. The 30ppi casting filter can effectively control the oxide inclusions in the melt to improve the quality of the cast rod, which is the common goal pursued by the aluminum industry.