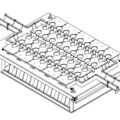

Cast aluminum bushing is one of the important parts before molten aluminum enters the mold.

Hot top casting is a casting method with a good heat preservation part at the top of the mold, which is used to slow down the initial cooling of the upper part of the mold, rather than slowing down the cooling rate of the first mold. Cooling of the whole mold.

Hot top ingot casting refers to the process of semi-continuous ingot casting of aluminum alloy by using the mold with heat insulation layer on the upper part.

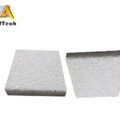

This kind of ingot casting process is usually to install a liquid storage tank made of refractory insulation material on the upper part of the semi continuous ingot mold of aluminum alloy, or evenly lay a layer of flexible thermal insulation layer on the upper part of the inner surface of the common mold. The function of this process is to keep the melt at a higher temperature when it enters the mold parts through the funnel.

Cast aluminum bushing is one of the important components of hot top casting platform.

The mould for hot top ingot casting is composed of a hot top part with heat insulation function and a non insulating part which can solidify and crystallize the melt.

The hot top not only keeps the melt warm, but also keeps the liquid column in the upper part of the ingot all the time, which provides a certain static pressure for the melt to be solidified and crystallized, and reduces the position of the solidified melt in the mold.

The height of the solidified crystalline part is usually between 20 and 50 mm, which is used to crystallize and shape the melt.

The technology level of the ingot is the same as that of the ingot, that is, the funnel is omitted, and the horizontal liquid feeding mode is adopted for melt transfer, so the quality and production efficiency are high. The ingot was improved.

The hot top ingot has uniform structure, good mechanical properties, smooth surface, light segregation resistance, and reduces the amount of chip and metal loss. At the same time, the hot top ingot casting method simplifies the production process and improves the working environment.