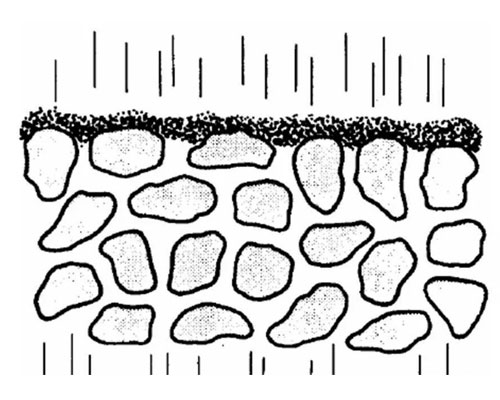

In cake filtration, two situations can be distinguished. Inclusions are deposited on the upper surface of the filter. Therefore, the size of the pores of the filter must be smaller than the size of impurities, or the filter cake is precipitated during the transition process from the deep bed to the filter cake, and the inclusions with too high solid content and smaller than the pore size are gradually blocked Filter and respectively cause the filter head to accumulate quickly. The latter guarantees pretreatment clarification methods, such as precipitation and flotation. In either case, the aggregates of inclusions act as a “second” filter, which increases the flow resistance and causes the particles to separate from the melt. Particle capture is almost entirely determined by the nature of the filter cake formed. Generally, in the entire aluminum manufacturing industry, the emergence of the cake mode is not well known.

This is because due to the large flow resistance experienced by the metal and the need for subsequent filter replacement, production has slowed down significantly. Therefore, when the concentration of inclusions is high or the area of the foundry is limited, the filter cake filtration is limited to the clarification of aluminum melt.

The ceramic foam filter (CFF) consists of a piece of open-cell ceramic foam with different thickness and cross-sectional area. The fineness of the filter manufacturing varies, usually 10, 20 and 30 ppi (pores per linear inch), and there is a tendency for fine pores (50, 60, 80 ppi). As the pore size decreases, the filtration efficiency and reliability of the filtration system will increase.

In the interstitial channel, under static flow conditions, particles are also trapped in the so-called “dead water”. There, as long as it does not cause undue interference to the metal flow, the inclusions may form slight adhesion, loose accumulation of suspended matter, and stay without any adhesion. The cause of particle release may be a change in flow rate or vibration. Therefore, particle capture can only be controlled to a certain degree within the range of 1-30 microns, and re-entrainment of captured particles cannot be ruled out. This uncertainty can explain the hazards of these particles rather than their size. The ceramic foam filter can be installed with minimal capital expenditure before casting. However, it has a limited service life because inclusions will form filter cakes during use, thereby increasing flow resistance.