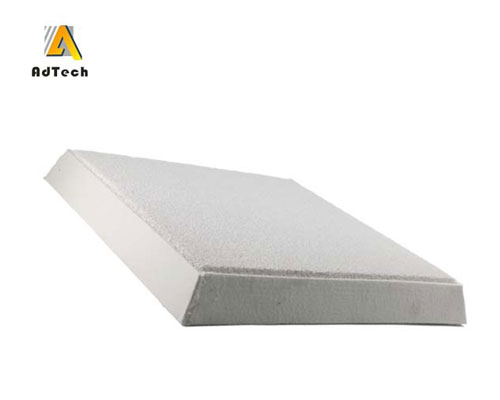

Buy ceramic foam filter depends on materials: alumina ceramic foam filters, silicon carbide ceramic foam filters, zirconia ceramic foam filters and Magnesium Oxide ceramic foam filters.

Buy Ceramic Foam Filter

1. In the process of bronze casting, SiC ceramic foam filter material is SiC.

2. Zirconia ceramic foam filter is used for casting steel parts. Zirconia ceramic foam filter material is ZrO2 zirconia. The zirconia of the filter has a heat-resistant temperature higher than about 1760 ℃, with very high strength and excellent high-temperature impact.

3. Alumina foam ceramic filter can effectively remove solid metal mixed with molten metal, so it can successfully forge aluminum alloy, aluminum foil manufacturing, extrusion processing technology and perfect aluminum products. The coarse porosity of 10ppi and the fine porosity of 70ppi are optional.

Buying ceramic foam filter, you need to consider many different aspects. Most manufacturers of these filters will provide manuals on filter conditions, such as maximum temperature and pressure. You can use our professional sales staff to record filter specifications. Details of each specific type of filter can be recorded, and you can compare the required filter to industry specifications before ordering. Even if the specification of the ceramic filter was not recorded before implementation, the quality of the casting will decline due to poor injection.