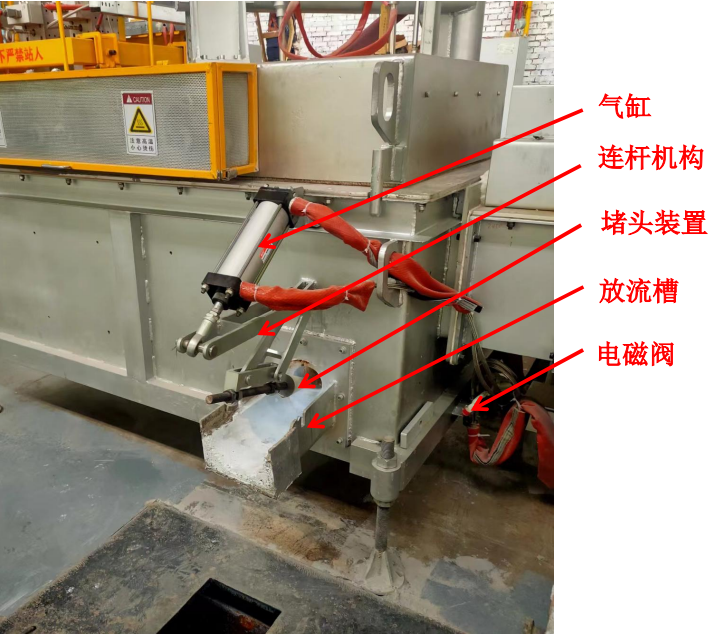

Automatic discharge device for filter equipment

The pneumatic automatic discharge device

The device includes: a cylinder, solenoid valve, connecting rod mechanism, plug device, discharge

groove;

How to use: Before the equipment enters the aluminum liquid, the solenoid valve is energized to control the extension of the cylinder and drive the connecting rod

the mechanism, plug the plug into the discharge port of the equipment, and the equipment starts to produce aluminum; when the production is over,

The solenoid valve is reversing and energized, the cylinder retracts, drives the connecting rod mechanism, pulls the plug device, and the box body

The internal residual aluminum flows into the slag pit on the ground through the discharge port and groove.

Advantages: The old discharge device is manually operated, and the operation of blocking and discharging the flow is performed manually; the pneumatic automatic

The device liberates manual processes, and the operation is simple and convenient; at the same time, the discharge of residual aluminum

cylinder

Plug device

Launder system

The electromagnetic valve

Linkage

At this time, the temperature of the molten aluminum is high, and there is a specific safety risk. The use of the device is not suitable.

Manually solves the security risk.

Application: The pneumatic automatic discharge device has been applied to the site of Northwest Aluminum Co., Ltd.