Aluminum silicate caster tip, also known as the casting nozzle, is a key component that directly transports and distributes the liquid metal to the casting roll during the continuous casting and rolling process. It is composed of upper and lower plate, several spacers, and side ears.

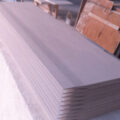

Material requirements of the feed nozzle. It is a kind of refractory board made of ceramic fiber and silicon aluminum fiber by vacuum pressing. It is a light-weight refractory product with the following properties:

- Good stability at high temperature

- Good heat preservation, low thermal conductivity

- Has good thermal shock resistance

- Does not react with molten metal, resistant to metal corrosion

- Good processing performance, the structure of the feed nozzle can be processed

Aluminum silicate caster tip is a reinforcing plate for the side ears, and the curvature of the cast-rolling roll and the thickness of the cast-rolled plate should be taken into consideration during processing. It cannot be made of non-aluminum alloy materials, because if the ears are taken out from the roll gap, the use of aluminum alloy materials will not damage the roll surface, and non-aluminum metal will damage the roll surface.

The production of the refractory insulation board is the same as that of the aluminum board. The board is made of hard refractory material, which has a certain elasticity and can also be processed and pressed by aluminum silicate fiber sheet.

The ear tips are processed from 1-3mm thick ductile graphite plates. The arc of the ears is required to be smooth and tidy. It is best to use a template to make the tip. After assembly, it should be closely matched with the roll. It can be made according to the difference of plate thickness and roll diameter.