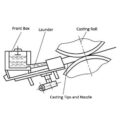

Aluminum alloy round rod casting platform is a tool to convert liquid aluminum into solid aluminum with certain shape and specification, which is the key part of casting molding. At present, the imported equipment represented by wagestaf of the United States has occupied the main domestic market. Our hot top accessories, including distribution launder, sleeve, graphite ring, tap hole cone, are suitable for aluminum rod casting.

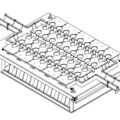

The general aluminum rod casting platform consists of three parts: upper platform, mold and ingot device.

The upper platform is an assembly made of steel structure and refractory. The lower part is a closed water chamber with cooling water, and the upper part is equipped with a chute containing molten aluminum to be cast. Each casting station has a drain tube for injecting molten aluminum into the mold. In addition, the upper platform is also equipped with lubricating oil and natural gas pipelines, water leakage pipelines, etc. A mold is a mold used for casting. It is the key part of forming ingot and determining ingot quality in casting process. It is required to have the characteristics of simple structure, convenient installation, high strength, good wear resistance and thermal conductivity. The starter device includes a lower platform and a starter head. The lower platform is a grid steel structure weldment. The starter head is installed on the lower platform to correspond with the mold one-to-one, and is connected to the casting top plate and upper platform in the casting well through the surrounding guide pillars. The starter head is a steel processing part, which is installed on the lower platform through the starter head screw. In the casting process, the front ingot head supports continuous solidification and longer aluminum rod, and slowly drops to complete the whole casting process.