Aluminum melt quality can generally be measured by two indicators: the content of inclusions in the solid structure and the hydrogen content in the liquid melt. When smelting aluminum and aluminum alloys, it is inevitable that the melt will be polluted by hydrogen and inclusions. Their content in the aluminum melt is an important indicator to measure the quality of the melt. Aluminum and its alloys exhibit the characteristics of easy oxidation and gas absorption during the smelting process, which makes it easy to form gases and inclusions in the aluminum liquid, which causes a series of defects such as air passages, pinholes, and inclusions in the final product, resulting in aluminum foil frequent strip breaks occurred during billet rolling, which seriously affected the production of aluminum foil.

Causes of Aluminum Melt Quality Defects

The non-metallic inclusions in molten aluminum are mainly metal oxide inclusions, part of which comes from the furnace charge, and most of them are formed by the reaction of aluminum and oxygen during the melting and casting process. The melting temperature, melting conditions, slag content in the furnace, The quality of the charge, the method of the converter, the masonry conditions of the furnace body, etc. all have an impact on the amount of melt inclusions. Aluminum reacts with O2, N2, CO2, CO, etc. in the furnace gas and finally produces alumina impurities.

The main reaction of aluminum melt to absorb hydrogen is the reaction of aluminum and water, and the reaction is irreversible. Below 250°C, aluminum reacts with water vapor in the air. A dense Al2O3 film is easily formed on the surface of pure aluminum, which can significantly hinder the reaction of aluminum melt with water. If the oxide film is destroyed, the reaction between molten aluminum and water will proceed more violently. The main way for hydrogen to enter the aluminum melt is the reaction between molten aluminum and water to generate free atoms [H]. Hydrogen is easily soluble in the aluminum melt. This reaction is the main way for the aluminum melt to absorb hydrogen.

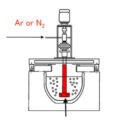

AdTech offers online degassing unit and CFF filter system for improving aluminum melt quality. Our equipment has been widely used by domestic aluminum factories. If you are interested in our products for molten aluminum purification, send email to sales@aluminiumceramicfiber.com.