In modern aluminum melt purification process, aluminum melt filters filtration is the last purification treatment process before casting. Prior to this, through furnace refining, standing, medium and non-medium adsorption, etc., although 60% to 80% of the inclusions and gases have been removed, there are still more fine inclusions dispersed in the melt. In order to obtain high-performance aluminum products, these fine inclusions must be collected and adsorbed and separated. Compared with other purification methods, the filtration method has become the preferred process for terminal purification treatment of aluminum melt due to its low energy consumption, convenient operation, high impurity removal efficiency and less secondary pollution.

Several Common Aluminum Melt Filters

Glass cloth and mesh filter: mainly rely on mechanical interception and separation of inclusions, with simple structure and low cost, suitable for filtering large particle inclusions. However, the filtering effect of fine inclusions is very small. In addition, the filter has low thermal strength, short life, and unstable filtration. It can only be used once, so it is mainly used for primary filtration of melt.

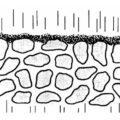

Deep bed filter (DBF): It is mainly composed of layered strengthened alumina balls stacked according to a certain particle size ratio. It can filter inclusions above 10μm. It has high filtration efficiency, large filtration capacity, long service life, and good reproducibility. However, it has high replacement costs, is susceptible to disturbances and short-circuits and inclusions desorption, etc., and the particle size of the filter ball is too small. Capillary resistance, so DBF is suitable for melt filtration with high performance requirements and large processing capacity.

Tubular filter (BPF): It is sintered with a special alumina binder with a particle size of 2-5 mm. The filtration is mainly performed by the tortuous gap between the particles. Its advantages are high thermal strength, low surface energy, low initial pressure head, high filtration efficiency (especially inclusions <20μm), large filtration capacity, low overall cost, and can be washed and used continuously for more than 20 d.

Honeycomb filter: It is formed by die extrusion or direct molding and sintering. It has the advantages of high strength, low filtration resistance, stable melt flow rate, easy replacement, and low cost. The disadvantage is that due to the limitation of the molding die, the pore size is large, and the filtration mainly depends on the pore wall to adsorb inclusions, and the filtration efficiency is low.

Ceramic foam filter (CFF) is currently the most widely used filter for aluminum melt filtration. Its advantages are high porosity, high filtration efficiency, convenient replacement, low cost, and strong adaptability. It can filter solid inclusions and separate some liquid inclusions. The disadvantages are low high temperature strength, short life (mostly for one use), and small filtration capacity.