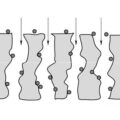

In the aluminum melting and casting process, the purity of the aluminum melt is related to the metallurgical quality of the ingot, so it is very important. Nowadays, there are three main methods for filtering aluminum melt impurities, namely: CFF (ceramic foam filter) filtration, DBF (deep bed filter) filtration, and tubular filter filtration.

CFF and DBF are based on the same deep filtration technology. Two technologies used on the corresponding products, to be able to meet the requirements of good quality.

Aluminum melt CFF filtration has a large number of used in actual production, it is a very common online filtration system, is used in the production of the standard products (rolling slab or crowdedPressure billet casting).

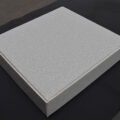

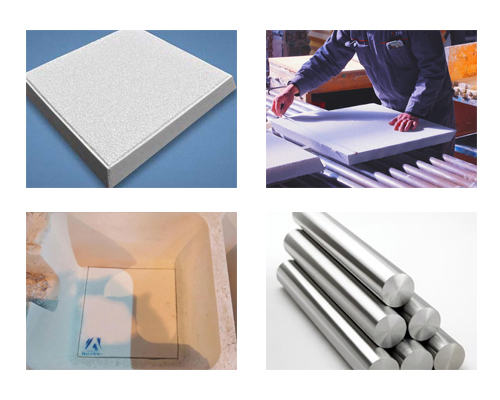

The use of ceramic foam filters to filter and remove impurities particles in the aluminum melt is now a relatively common filtering method. This ceramic foam filter molten metal filtration method has the advantages of low cost, convenient use, simple structure, etc., and can meet the requirements of most products. The ceramic foam filter is stalled in aluminum melt filter box, mainly used to filter the impurities of the aluminum melt online, and provides high-purity aluminum liquid for the casting stage. In order to install the filter plate, the filter box is equipped with the installation interface of the filter plate.

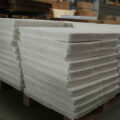

The deep bed filter is a new type of filter device developed in recent years. It is composed of multiple layers of alumina balls and a layer of alumina grit of appropriate size. The size and stacking method of alumina balls and gravel are determined according to the quality requirements of the final product.

DBF deep filtering technology is used below the condition that the thicker, it has become more prominent filtration efficiency, more suitable for the mass production of thin products, like can or aluminum foil (use eventually is thin aluminum foil), as well as on the surface of the product (PS version of the substrate or light anodic oxidation) and capacitor foil.