The aluminum liquid filtering device is composed of an aluminum liquid filter box and a filter plate. The metal aluminum liquid enters from one side of the filter box. After impurities are filtered by the filter plate, the cleaner aluminum liquid flows out from the other side of the filter box. The disadvantage is that the existing filtering devices are only provided with one filtering plate, and the filtering accuracy is limited.

In order to obtain aluminum liquid with higher filtering precision, the current method is double or multi-channel filtering. The characteristic is that two or more CFF filter boxes are arranged in sequence. Each CFF filter box is a single-plate filtration method. From front to back, the accuracy of the filter plates in the filter box is sequentially improved. That is, a thicker filter plate is used in the front and a fine ceramic foam filter plate is used in the back. The aluminum liquid flows out of the front filter box and then enters the next filter box to be filtered again. Finally, a higher cleanness metal aluminum liquid is obtained.

The disadvantage of this multi-channel filtration method is that although it is better than single-board filtration, the filtration accuracy is limited. Although aluminum passes through the process of distribution and integration, it is beneficial to alloy processing. At the same time, according to the theory of heterophase, the heterophasic polymerization grows into metastable coarse particles and disintegrates into fine particles as the liquid diffuses again, making the next layer of filter plate unable to capture, so the filtration accuracy is still limited. At the same time, this multi-channel filtering method causes a waste of materials.

Aluminum Liquid Filtering Device with Double Layer Filter

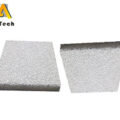

Provided is a new aluminum liquid filter device with low manufacturing cost and high filtering precision. The utility model is mainly composed of a CFF filter box and a built-in upper and lower filter plates. The two ceramic foam filters are arranged from top to bottom with a pore size from thick to fine, with a certain gap left in between. After the metal aluminum liquid flows in from the inlet end of the filter box, it is sequentially filtered through two coarse and fine filter plates to obtain a higher cleanliness aluminum liquid.

This device does not need to manufacture new equipment, can be used directly on the original filter box, and only one filter box is needed, which greatly reduces the manufacturing cost, at the same time, the actual use is very strong, and the filtering accuracy is high, so it is an ideal high-cleanliness aluminum liquid filtering device.

The accuracy of the two ceramic foam filters is from coarse to high from top to bottom, with a certain gap between them. After the metal aluminum liquid flows in from the inlet end of the filter box, it is sequentially filtered through two coarse and fine filter plates to obtain a high-purity aluminum liquid. For example, two filter plates such as 30ppi and 60ppi are placed up and down in the same filter box, and the two-stage spacing is designed according to the flow rate. In use, the filter accuracy of the filter plate can be flexibly selected according to the product requirements. When the aluminum liquid passes through the first-stage filter plate, the distribution and integration process is a very good alloy treatment process. At the same time, according to the theory of heterophasic polymerization, the particles that could not be captured by the original 60ppi generated aggregates and grew up, and the second stage was not decomposed by diffusion. The ceramic foam filter plate captures, so that the two-stage filtering accuracy can be greatly improved.