The aluminum foil is made of aluminum alloy containing 92% to 99% aluminum. The thickness of the foil is usually 0.00017 to 0.0059 inches, can produce a variety of widths and strengths, can be used in hundreds of applications. It is used to manufacture insulation materials for the construction industry, fin materials for air conditioning, electrical coils for transformers, capacitors for radios and TVs, storage tanks, decorative products, and insulation materials for containers and packaging. AdTech offers ceramic caster tips for aluminum foil casting and rolling.

Aluminum Foil Casting

The popularity of aluminum foil in many applications is due to several main advantages, and one of the most important advantages is the abundant raw materials required for aluminum foil manufacturing. Aluminum foil is cheap, durable, non-toxic and oil-proof. In addition, it can resist chemical corrosion and provide excellent electrical and non-magnetic shielding.

Aluminum foil is made of thin metal leaves with a thickness of less than 0.2 mm (8 mils). Usually, a thin aluminum foil with a minimum thickness of 0.006 mm (0.2 mils) can also be used. In the United States, foil is usually measured in mils. The foil is flexible and can be easily bent or wrapped around objects. Thin foil is fragile and is sometimes laminated to other materials (such as plastic or paper) to make it more useful. Aluminum foil replaced tin foil in the mid-20th century.

Aluminum Foil Rolling

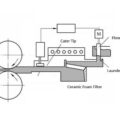

The production method of aluminum foil is to roll the ingot cast from molten aluminum, and then re-roll it to the required thickness on the sheet and foil rolling machine, or through continuous casting and cold rolling. In order to maintain a constant thickness in the production of aluminum foil, beta rays will pass through the aluminum foil to the sensor on the other side. If the strength is too high, the roller will adjust, increasing the thickness. If the strength is too low and the foil becomes too thick, the roller will apply more pressure, making the foil thinner.

The continuous casting method consumes much less energy and has become the preferred method. For products with a thickness of less than 0.025 mm (1.0 mil), the two layers are usually put together for the final pass and then separated to produce a foil with a glossy surface and a glossy surface. The two sides that are in contact with each other are matte and the outside is brightened. This is done to reduce tearing, improve productivity, control the thickness and avoid the use of smaller diameter rollers.