The aluminum melt filtration treatment after the hydrogen removal is the most effective and reliable means to remove non-metallic inclusions. There are many kinds of filtering methods, the most effective ones are corundum filter tube and foam ceramic filter plate. The corundum tube filter has high filtration efficiency, but it is expensive and inconvenient to use. Foam ceramic filter plate is characterized by convenient use, good filtering effect, low price, and is widely used all over the world. Aluminum alloy melts in developed countries are all filtered by foam ceramic filter plates.

At present, most aluminum foundries use a box-type ceramic foam filter system, which is a filter box with a gas preheating cover system. When the molten aluminum passes through the ceramic foam filter plate, the inclusions in the melt are mechanically blocked by the filter to achieve the purpose of eliminating separation. This aluminum melt CFF filtration treatment method has a good filtering effect.

CFF Filter Mechanism

After the molten metal passes through the filter, it becomes a smooth laminar flow state, which prevents the molten metal from entrapment of gas, reduces the erosion of the cavity by the molten metal, exerts the slag blocking function of the gating system, and avoids secondary oxidation slag.

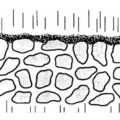

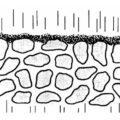

There are a large number of oxide inclusions, slag and other large impurities in the molten metal. By selecting a foam ceramic filter with a suitable pore size, a large number of inclusions can be screened out.

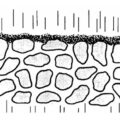

The ceramic foam filter has a three-dimensional vertical structure, which can effectively block slag mechanically. Many inclusions larger than the pore size of the filter are trapped at the entrance of the filter. As the number of captured inclusions increases, a filter cake composed of large inclusions is formed at the entrance of the filter. The filter cake makes the liquid flow thinner, so that inclusions smaller than the pore size of the filter are also partially captured on the “filter cake”.

The ceramic foam filter has a large specific surface area, which is conducive to the adsorption of a large number of fine impurities. This adsorption is mainly physical adsorption of intermolecular gravity.