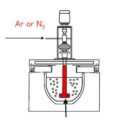

Aluminum degassing units can reduce gas accumulation and problems and achieve the highest refining efficiency. Online degassing unit adopts advanced high silicon melting technology to get a long service time, degassing rotor, heater protection thimble and thermocouple protection thimble adopt ceramic manufacturing technology.

Aluminum degassing units are used for hydrogen (H) and slags removal from molten aluminum. The online degassing unit has dual functions: processing and heating. It serves high precision molten aluminum purification industry.

Aluminum Degassing Units

The accumulation of gas greatly limits the refining degassing rate. As bubbles rise to the surface, the accumulation of gas will form smaller and smaller bubbles. Large bubbles will increase the interface interference between the aluminum melt and the scum layer, resulting in a certain amount of reflux, so that impurities in the scum will enter the molten aluminum again. The smaller bubbles reaching the top of the molten aluminum can minimize this pollution source.

More importantly, the contact area between gas and molten metal is greatly reduced due to the accumulation of large bubbles. Because the reaction occurs only at the gas metal interface, it will lead to a significant decrease in the refining reaction rate. Hydrogen is highly dispersed in aluminum melt, and the transfer reaction is mainly controlled by the interfacial area. The larger the interface area, the shorter the time required to reach a certain degree of degassing.

In addition, the larger the interface area, the greater the chance for bubbles to encounter and capture impurities. Therefore, the larger the interface area, the higher the degassing refining efficiency. With the decrease of bubble number and contact area between gas and metal, the possibility of contact, adhesion or reaction between some impurity and bubble will be greatly reduced.

When cold gas is injected into molten metal in the form of fine bubbles, the gas will expand rapidly according to the law of ideal gas to form larger bubbles. From room temperature to molten aluminum temperature, the volume of refining gas (AR or N2) will be tripled. If this expansion is not allowed before the gas is cut into tiny bubbles, the expansion of the bubble will lead to a decrease in efficiency.

In addition, the bubble volume expansion will increase the buoyancy of the bubble and its upward movement speed in the melt. Therefore, it is important to preheat the gas to a temperature close to the molten aluminum before it enters the molten metal. In the on-line degassing system, gas preheating is realized by its own precision equipment.

It makes the gas flow between the inner wall of the graphite sleeve and the groove machined on the outer surface of the rotating shaft, thus increasing the flow path of the gas on the rotating shaft by 20 times. The larger gas surface allows heat to be transferred rapidly from the casing (or reactor) to the moving gas.