Aluminum Casting Flux is used in a variety of aluminum alloy melts, and can be used for pure aluminum smelting, refining and slagging.

When using, just sprinkle the refining agent on the surface, then quickly dissolve it in the aluminum liquid, and then fully stir it.

If a jet is used, it is best to use an inert gas to inject the refined agent, for example, nitrogen and argon can be selected.

Aluminum Casting Flux application range and dosage:

1. When the slag gas content of general cast aluminum flux is required to be high, degas and remove slag from non-high magnesium aluminum alloy and pure aluminum.

2. Except for high magnesium, all aluminum alloys are mainly degassed, the furnace charge used is polluted, the melt gas content is high, and the main bubbles in the casting are always the main quality.

3. Cast aluminum refining agent is mainly used for slag removal. It is used to melt coarse particles with a large surface area. The content of oxidized inclusions is high. Most non-metallic inclusions in castings are main quality problem.

4. Refining and refining degassing, slag removal and purification effect is good, suitable for aluminum alloy and aluminum alloy with aluminum-silicon alloy content less than 4%;

5. Refining and modifying aluminum-silicon alloy, degassing, removing slag and modifying;

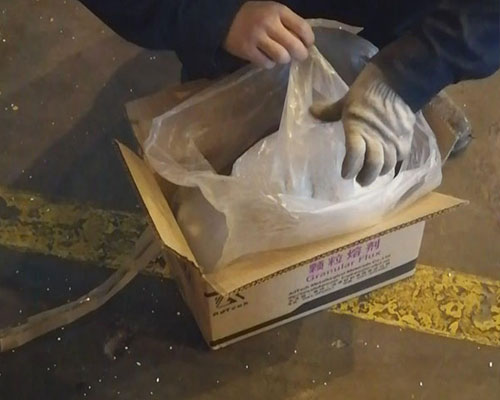

How to use Aluminum Casting Flux

1. Within the refining temperature range, install a quantitative amount of cast aluminum refining flux into the dust collector storage tank.

2. Blow in nitrogen, then turn on the switch under the refining tank.

3. When the iron pipe has cast aluminum refining agent, insert the iron pipe into the aluminum liquid to move horizontally.

4. The insertion depth should be 3/4 of the depth of the molten aluminum at the end of the iron pipe. Move the iron pipe back and forth 2 to 3 times. Do not touch the furnace wall to prevent the pipe from entering.

5. After the refining is finished, pull the iron pipe out of the molten aluminum and turn off the nitrogen.