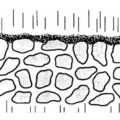

Foam ceramic filters are commonly used for aluminum liquid filtration. When the molten aluminum passes through the pores in the Aluminum Casting Ceramic Foam Filter, the impurities inside are deposited on the walls of the pores under the action of fluid power, inertia, interception, collision, adsorption, etc., so that the clean molten aluminum enters the cast-rolling flow plate.

The filtration efficiency of the Aluminum Casting Ceramic Foam Filter is directly related to the diameter of the micropores, but the diameter of the trapped debris is much smaller than the average diameter of the micropores. The filter plate with 12 holes/cm and thickness of 50mm can remove 80% of debris and other debris above 100μm.

In order to improve the filtration efficiency, you can also use glass fiber mesh for coarse filtration first, and then use foam ceramic filter plates for fine filtration. Foam ceramic plates are usually replaced once per heat to ensure the passing capacity of the molten aluminum and prevent the debris and slag particles deposited in the channels from re-entering the molten aluminum.

The method of purifying molten aluminum in the furnace can only remove the aluminum material itself and the impurities newly added in the melting process, but cannot eliminate the secondary pollution of aluminum during the injection process. At the same time, because the furnace area is large and the depth of the molten pool is shallow, it is difficult to spread the flux to every corner of the furnace in order to effectively purify all the molten aluminum.

Therefore, in the melting and casting process, the on-line purification treatment method outside the furnace is generally used, so that the aluminum liquid is convectively contacted with the gas flux in a special vessel after the flow of the furnace or the static furnace, and then flows into the semi-continuous casting mold or continuous casting The rolling feed nozzle ensures that all the molten aluminum is effectively purified and prevents secondary pollution.