In order to ensure that the aluminum melt has sufficient fluidity to pass through the aluminum casting ceramic foam filter, the temperature of the aluminum melt in the fixed furnace is usually increased by 3~5°C (higher than the unfiltered temperature). The temperature at which the aluminum melt contacts the ceramic foam filter should not be lower than 680~690°C. The increase in temperature allows the aluminum melt to absorb the heat of the ceramic foam filter and still ensure sufficient fluidity to pass through the ceramic foam filter (especially in the initial stage).

The aluminum liquid hardly wets the ceramic foam filter. The force formed by the surface tension prevents the molten aluminum from entering the ceramic foam filter. Inside, the liquid aluminum should have enough pressure head to balance the surface tension, that is, the aluminum melt can pass through the ceramic foam filter. The ceramic foam filter does not need a high pressure head when filtering, and the initial pressure head is 100~150 mm. It can pass smoothly even in the filtration process of about 10 mm.

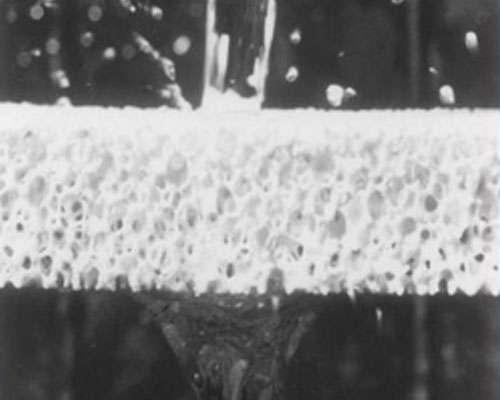

The aluminum casting ceramic filter immersed in the aluminum melt is tightly plugged with silicate wool. Liquid aluminum can only pass through the serrated holes of the ceramic foam filter. Due to the combined effect of axial pressure, friction, surface adsorption and chemical forces of liquid flow. The inclusions carried in the aluminum water are firmly retained in the pores of the ceramic foam filter. The surfaces and gaps in the cave are separated from the liquid phase of the metal.

The effect of aluminum slag depends on the pore size and thickness of the ceramic foam filter for casting, and the speed at which the aluminum melt passes through the filter. The thicker the ceramic foam filter, the smaller the pore size, the longer the aluminum liquid flows through the ceramic foam filter, and the greater the chance of collision. In addition, the inclusions are retained, and the chance of depositing and adsorbing on the pore wall is greater.

It should be noted that when the speed of the filtrate flowing through the ceramic foam filter is too low, it is not easily absorbed and cannot flow smoothly through the filter pores. When the rate of change is too high, the flow of liquid metal will wash away solid inclusions from the hole walls and may remove them. The optimal flow rate is determined by production practice.

Ceramic foam filter Dimension

660x660x50(26″)

584x584x50(23″)

508x508x50(20″)

432x432x50(17″)

381x381x50(15″)

305x305x50(12″)

228x228x50(9″)

178x178x50(7″)

Ceramic foam filter Pore Size(PPI):10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.