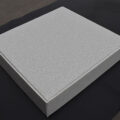

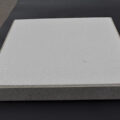

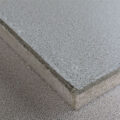

The aluminum cast ceramic foam filters have a complex foam ceramic structure, which can effectively block slag.

The aluminum cast ceramic foam filters use a three-dimensional network structure and an organic foam with connected pores as a carrier, and invades it into a special ceramic slurry with thixotropy, and adopts a special roll extrusion process to make the ceramic slurry evenly spread on the carrier. On the skeleton, it is dried and cured, and then fired at a high temperature.

Aluminum alloy is easily oxidized and mixed. Therefore, the prevention and removal of gas and oxide inclusions have become the most prominent problem in the aluminum alloy melting process.

The slag inclusion defects in the castings greatly affect the production efficiency and economic benefits of the iron casting plant. The large surface inclusions will reduce the surface finish of the casting, and in severe cases, the casting will be directly scrapped.

The defects of subcutaneous inclusions are usually only found in the processing stage, assembly stage or actual use stage. For example, in the processing workshop, the presence of macroscopic or microscopic inclusions will reduce the machinability of castings and the life of machining tools. Inclusions in the assembly or use process will reduce the mechanical properties or use performance of the casting, such as leakage under pressure. Castings that are scrapped during processing, assembly, or use usually cause higher losses because many operations have been performed before.

In order to obtain high-quality aluminum alloy liquid, its smelting process must be strictly controlled and measures must be taken to control it.

When the molten aluminum passes through the complicated Ceramic Foam Filter, inclusions accumulate on the surface of the filter, gradually forming a layer of “filter cake”, making the flow channel of the molten aluminum smaller.

At the same time, the media also has a filtering effect. These can intercept inclusions, and there is also a “filter cake” effect inside the filter. Therefore, the surface of the filter medium can filter out finer inclusions.