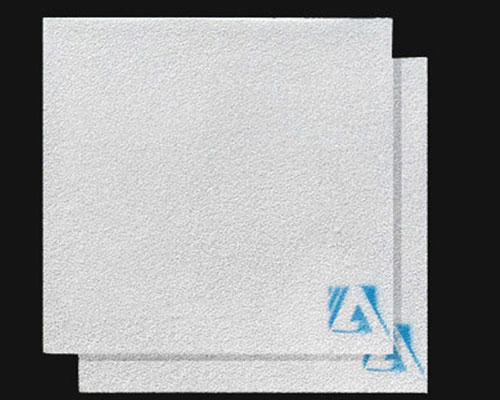

The aluminum cast alumina ceramic filters are very important to the quality of the aluminum melt, and have a great influence on the subsequent processing performance and the quality of the final product.

Aluminum cast alumina ceramic filters have many advantages such as good chemical stability, high specific strength, high temperature resistance, thermal shock resistance, and large specific surface area. Ceramic foam filter is widely used in metallurgy, chemical industry, environmental protection and other fields.

In terms of metallurgy, the use of ceramic foam filter plates to remove foreign impurities in the aluminum melt, such as slag and inclusions, is one of the most effective melt purification methods.

Slag and inclusions are the main reason for the shrinkage defects of castings. The reason is that liquid shrinkage is greater than solid shrinkage. It was found in production that the smaller the solidification range of cast aluminum alloys, the easier it is to form concentrated shrinkage cavities, and the wider the solidification range, the easier it is to form dispersed shrinkage cavities.

Therefore, the design must make the cast aluminum alloy conform to the principle of sequential solidification, that is, the volume shrinkage of the casting from the liquid state to the solidification should be supplemented by the alloy liquid, and the shrinkage and porosity are concentrated in the outer layer.

Fluidity refers to the ability of the alloy liquid to fill the mold. The fluidity determines whether the alloy can cast complex castings. Eutectic alloys have the best fluidity among aluminum alloys.

As the requirements for the quality of aluminum products are getting higher and higher, the requirements for the filter plate are also getting higher and higher. The aluminum cast alumina ceramic filter can reduce the inclusions in the aluminum liquid, reduce the shrinkage defects, and can also make the turbulent flow of the aluminum liquid become laminar.