The remelting of foil scrap has presented an especially difficult problem because of the extreme thinness of the metal sheet compared to area, and the resultant ease of oxidation in the melting furnace. The melt obtained from reclaiming foil scrap, therefore, contains a large number of oxide particles and occluded gas. To render the metal fit for subsequent use, it must be treated to remove the effect of the gas in creating blowholes or other void spaces in the casting. The purification of aluminum and aluminum alloy melts is carried out by removing entrained gaseous impurities and solid particulate impurities (mainly alumina) through online rotary degassing equipment and filtering equipment.

Molten aluminum is usually contaminated with hydrogen and unwanted elements such as sodium, calcium, and lithium. If the content of magnesium in the melt is too high, the excess magnesium will also be regarded as a pollutant; and vice versa. However, when processing many aluminum melts, the magnesium content is not excessive, and it is desirable to remove hydrogen and other harmful elements without significantly changing the magnesium content in the melt.

Existing proposals for the removal of the above-mentioned pollutants include the use of gas bubbled through the melt to chemically react with impurities or physically remove impurities. Suitable gases include inert gases, such as argon and nitrogen; reactive gases, such as chlorine (from chlorine-containing salts, chlorine-generating tablets, usually hexachloroethane, chlorine and halocarbon gases) and fluorine; and inert gases a mixture of nitrogen and argon or a mixture of reactive gases (chlorine and fluorine).

Three physical mechanisms are active in removing these elements. When the above type of gas is introduced into the melt, the hydrogen present in the melt will diffuse into the rising bubbles, and the slag particles will adhere to the surface of the bubbles. In addition, the element to be removed may react with one or more of the gases introduced into the melt.

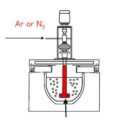

Rotary degassing device is mainly used to remove hydrogen and slag from molten aluminum. Aluminum alloy rotary degassing system uses a patented rotor impeller principle, which can generate tiny inert bubbles and mix with the melt. These small bubbles are evenly distributed on the surface of the melt, thereby maximizing the contact area between the inert gas and the melt. Effective means that a higher level of degassing and cleaning can be achieved, and processing time can be reduced.