Aluminum alloy degassing purification is a basic step in the production of aluminum alloy. It can reduce the hydrogen melted in the solid metal, improve the purity of the metal by reducing impurities, and reduce the alkali metal content in the final alloy to obtain purer aluminum liquid.

Aluminum Alloy Degassing Purification are achieved by blowing mixed gas into the molten metal. The contact surface between the bubbles and the molten metal produces a physical and chemical reaction, which reduces the floating capture of fusible diffusible hydrogen and solid impurity particles.

There are two ways for aluminum alloy degassing purification. One is static purification and degassing, which is carried out in the casting melting furnace. The other is online purification degassing, using a set of specially designed equipment between the casting melting furnace and the casting machine.

The purification of the molten aluminum in the furnace is very limited. To further improve the purity of the aluminum alloy melt, it is more important to rely on online purification treatment outside the furnace to more effectively remove harmful gases and non-metallic inclusions in the aluminum alloy melt and produce high-grade cast aluminum alloys.

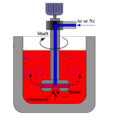

Hydrogen removal can be removed by dispersing neutral gas (Ar or N) in an online degassing system and contacting molten aluminum. The best hydrogen removal efficiency is achieved by increasing the exchange area between dissolved hydrogen and molten aluminum, that is, to reduce the size of the bubbles as much as possible.

The functions of the online purification and degassing system are as follows:

(1) The contact is more effective and the amount of reaction gas required can be reduced.

(2) Reduce air pollution.

(3) Make the metal solidify in a shorter time and reduce the oxygen content in the end product.

(4) Reduce the amount of aluminum dross, and further reduce the turbulence of the metal surface.