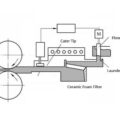

Aluminium Foundry Casting line for the production of posts from aluminum by the method of heat nozzle.

A BRIEF DESCRIPTION

Aluminium Foundry Casting line provided including:

SPRUE BUSH

DISTRIBUTING LAUNDER

HAT PLATE

TRANSITION PLATE

GRAPHITE RING

HOP-TOP CASTING DISTRIBUTING LAUNDER

The proposed set of equipment of the Foundry line is equipment for casting high-quality workpieces by the method of thermal packing, which meets the world requirements of modern industry.

Today in Southeast Asia there are about 700 lines of this type with a wide range of productivity: from 100 to 6,000 tons per month.

Equipment provides for the following main elements:

CASTING TABLES WITH HEAT NOZZLE

The design of casting tables is specially designed in such a way as to facilitate the operation process as much as possible, namely: removal / installation of molds, cleaning and those. maintenance of the inside of the table, change of tables and autonomous hydraulic rotary cylinders to facilitate the process of removing the posts after melting.

This modern development has passed production testing at a large number of enterprises in southeast Asia for 15 years, and the simplicity of design eliminates any problems in operation. The design uses ceramic materials that are not inferior to world analogues

Which are specially designed for our enterprise by a leading institute.

Non-ferrous metallurgy of China.

Aluminium Foundry Casting line -CASTING MACHINE

A cost-effective and virtually maintenance-free installation is proposed, which is presented in the form of 4 suspended steel cables wound onto one Drum without the help of guides.

HOMOGENIZATION LINE

The proposed homogenization line presents the most advanced solutions in the arrangement of gas and control equipment. The design is distinguished by reliability, functionality and performance. The gas system of the leading European manufacturer Krom Scroder was used.

Aluminium Foundry Casting line -COOLING TOWER

For the water circulation system, a specially designed water cooling system is provided – a cooling tower, which includes a cooling system, a control system, a cleaning system, and an emergency automation system.

The system is designed taking into account the step-by-step operation, i.e. it is possible to work in an economical mode (with one cooling tower), and when reaching rated capacity in maximum mode, which saves significant energy resources.

SCOPE OF DELIVERY AND GENERAL DESCRIPTION

The proposed casting line includes the following types of equipment:

Trough from your smelter to the foundry table. Degassing system. Two-box filtration system with electrically heated filters. Refining system (filing of bar ligature). Casting tables with heat nozzle. Casting control system. Line trimming ingots. Complete homogenization system. The water system is a cooling tower.

C General technical specifications of the equipment supplied