When the metal melting composition is adjusted, the next step is the refining process of molten aluminum. The purpose of aluminium alloy refining is to obtain a high-cleanliness, low-gas content alloy liquid after taking degassing and impurity removal measures. There are several methods of aluminium alloy refining:

Add chloride (ZnCl2, MnCl2, AlCl3, C2Cl6, TiCl4, etc.); aeration method (pass in N2, Cl2 or N2 and Cl2 mixture); vacuum treatment method; add non-toxic refining agent method; ultrasonic treatment.

According to its principle, the aluminium alloy refining process has two functions: for dissolved hydrogen, the hydrogen is separated from the aluminum liquid mainly by diffusion; for oxide inclusions, it is mainly removed by the adsorption of flux or bubbles on the surface of the medium.

In production, during the solidification of the aluminum alloy solution, hydrogen atoms in the aluminum alloy solution spontaneously form hydrogen molecules. Hydrogen molecules and non-metallic inclusions form bubbles during solidification, and inclusions are the main cause of defects in aluminum alloy castings. Most of the impurities and gases in the aluminum alloy solution come from the reheating material, so when the aluminum alloy is smelted, the refining treatment of the aluminum alloy solution is essential.

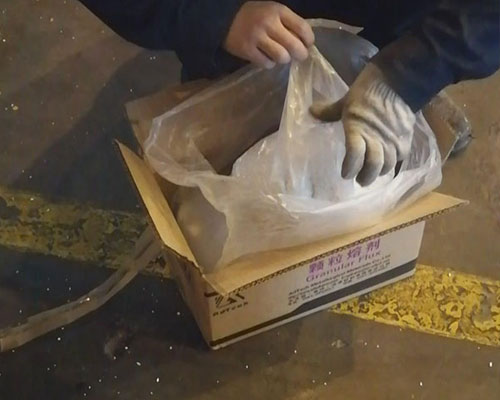

The refining agent is a white powder or granular flux, which is prepared by mixing a variety of inorganic salts after drying treatment in a certain proportion. It is mainly used to remove hydrogen and floating oxidized slag inside the aluminum liquid. Part of the components in the refining agent is easily decomposed at high temperatures, and the generated gas is prone to hydrogen reaction, and has a strong adsorption force with slag inclusions, and quickly escapes from the melt. Other components have the effect of slag cleaning agent.

How to use refining agent: Sprinkle the refining agent on the liquid surface, quickly press it into the molten aluminum, fully stir and let it stand for slag removal; for example, with the help of a sprayer, spray the refining agent into the molten aluminum with inert gas. The general dosage is about 0.3% of the weight of the molten aluminum, depending on the purity of the molten aluminum.