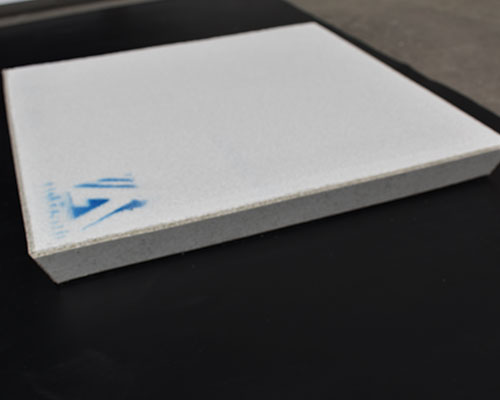

Alumina ceramic foam filters for casting are widely used in the production of aluminum profiles, aluminum foil, and aluminum alloys. The size is available in square, and custom geometric shapes; sizes ranging from 10mm up to 600mm, and thicknesses from 10-50mm. The most common porosities are 10ppi, 20ppi, 30ppi, 40ppi, 50ppi, 60ppi.

1.10-30ppi continuous casting and rolling of aluminum alloy bars

2.30-50ppi semi-continuous casting

3.40-50ppi for high-quality aluminum profiles and plates

4.50-60ppi for double zero wave continuous casting and rolling

Alumina ceramic foam filters for casting are mainly used for filtering aluminum and aluminum alloys in foundries. Alumina ceramic foam filter has excellent resistance to corrosion and corrosion of molten aluminum, to effectively remove large impurities in the aluminum liquid and absorb micro-level fine impurity particles, reduce residual gas and provide laminar flow, and then make the filtered metal obviously more transparent. Cleaner metals can produce higher quality castings, less scrap, and fewer inclusion defects, all of which help increase profits.

Advantages of Alumina Ceramic Filters for Casting

- High strength, no loose ceramic particles or powder

- Three-dimensional connected mesh structure, high porosity

- Large surface area for slag collection and large surface area for filtration

- Excellent thermal shock resistance

- Particles larger than the pore size are captured on top of the ceramic foam filter

- Smaller particles are trapped on the filter cake by larger particles

- Fine particles are trapped in the pores of the filter

When using a foundry ceramic foam filter, install a ceramic filter in the CFF filter box. The molten aluminum is poured into the filter box through the Ceramic Foam Filter China, and the filter captures the fine particles in the molten metal. After the casting operation is completed, the aluminum slag remaining in the ceramic filter forms an almost solid aluminum mass.

Aluminum Foundry Filters can remove a large number of such inclusions from the molten aluminum. Foam ceramic filtration technology has become the main filtration method for commercial aluminum alloys all over the world. Due to its low installation and operating costs and ease of use, the technology has rapidly expanded to aluminum foundries of various types and levels of complexity.