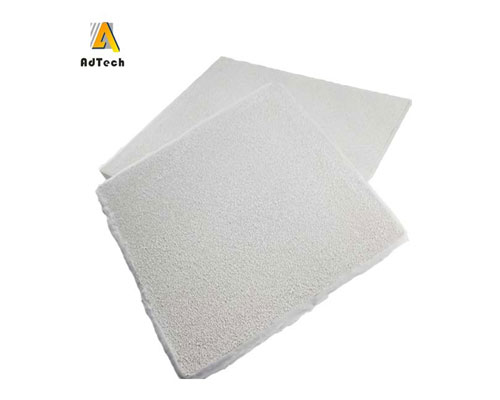

Filtration is an important part of every manufacturing and foundry industry. Different industries use different materials to filter finished products. Alumina ceramic filter is used for aluminum foundry.

As we all know, aluminum is the best material for a variety of applications, and foundries help to make molten aluminum molds into different structures to better utilize the metal.

However, the process will remain incomplete unless it is filtered with efficient tools. The presence of impurities and other harmful products in the metal reduces the quality of the metal, thus reducing the quality of the material cast by the metal. The ultimate goal of a foundry is to make profits, and the high quality of casting materials can help to achieve this goal.

Performance and application of aluminum filter

The Alumina Ceramic Filter can operate at 1200 ℃.

It is highly porous and helps to absorb molten metal, leaving impurities behind.

It has high thermal shock resistance.

Higher physical and chemical stability

Alumina foam ceramic filter can be used for non ferrous alloys of aluminum.

It can also be used as a catalyst for different chemical reactions and for chemical filling of different materials.

The Alumina Ceramic Filter is also used to filter high temperature gases.

The fabrication of alumina ceramic foam filters involves different industries. It’s made in different shapes and sizes. You can send an email directly to sales @aluminiumceramicfiber.com.