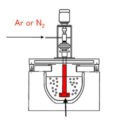

Alu Refiner is made of a variety of salt compounds by special process, using a refining powder sprayer with nitrogen as a carrier, and evenly spraying it into the aluminum liquid, thereby achieving double purification of the melt by gas and flux. This product is in aluminum It is widely used in the processing industry.

Alu Refiner

Alu Refiner has a large market demand and broad application prospects. Has the following advantages

1. It has the advantages of combining gas refining and flux refining, and the degassing effect is better;

2. Low addition, simple and convenient operation, reduce labor intensity of workers;

3. The utilization rate of the flux is high, which effectively realizes the degassing and slag removal of the melt.

Technical indicators and characteristics

Use temperature and method

1 traits: white powder

2 Applicable alloy: used to melt pure aluminum and various commonly used aluminum alloys;

3. Operating temperature: 700~780℃;

4 Recommended dosage: Add 0.1~0.4% of the weight of aluminum liquid.

Analysis of product application fields and market prospects

It is mainly used for smelting pure aluminum, aluminum alloy and recycled aluminum to remove scum on the surface of aluminum liquid, and can absorb slag near the surface layer, and can also be used for frying slag. It is one of the fluxes that must be used for aluminum and aluminum alloy smelting. It has large market demand and broad application prospects.

The common methods of degassing and rotary refining are degassing refining and powder refining. The principle is to pass inert gas or refining agent to the bottom of the furnace. The refining agent is very light. The inert gas or refining agent starts to rise from the bottom of the furnace. Take away the hydrogen and scum in the aluminum liquid, so as to achieve the purpose of purifying the aluminum liquid.

The degassing machine used for degassing and refining drives the flange through the motor, and the flange is connected with the graphite rotor to rotate.

The general graphite rotor has a relatively short life and is prone to corrosion and fracture. For this reason, the graphite rotor is immersed in a medium under high temperature and high pressure, and then sintered and solidified to increase its service life. This type of graphite mainly depends on imports and has high cost.