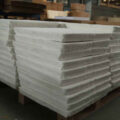

Alu Metal Filtration is the last purification process close to the casting.

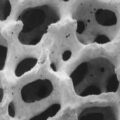

Previously, after flux refining in the furnace, standing ups and downs, and online degassing outside the furnace, although 60% to 80% of the inclusions and gases have been removed, there are still more subtle “miscellaneous hydrogen” particles dispersed in the melt. .

And in the process of refining and flow, new inclusions are produced. Before casting, these fine phases must be aggregated and grown and separated.

Compared with other purification methods, the ceramic foam filter filtration method has become the preferred process for terminal impurity removal due to its low energy consumption, simple operation, low labor intensity, high impurity removal efficiency and low pollution.

Russian Aluminium indicates that aluminum alloys are widely and deeply used in structural materials such as aerospace, shipbuilding and automotive industries, and defense industries.

These industries also put forward higher requirements for the strength, corrosion resistance, and elongation of materials.

As a military power, Russia puts forward almost harsh requirements on aluminum alloy castings in the sophisticated aerospace and military industries.

It is required that the castings should not have serious smelting and casting defects such as obvious pores, slag inclusions, inclusions, cracks, segregation, and porosity.

Therefore, Alu Metal Filtration slag removal has become the primary task of many aluminum casting workers.

Russian Aluminium stated that Alu Metal Filtration is the last step in the purification of aluminum melt, which is particularly important.

It needs to be particularly pointed out that it is necessary to prevent the secondary pollution of the melt that may occur during the process of solidification and forming after the aluminum melt leaves the filter box.

In this process, the launder, front box, distribution plate, and hot cap made of fused silica ceramics with long life, high strength, non-stick aluminum and good heat insulation are used, and dehumidification and cleaning are timely to eliminate possible pollution sources. It can not be ignored to ensure the cleanliness of aluminum melt.