The mechanism of adsorption purification method is that the aluminum alloy melt is in direct contact with N2, Cl2 and other gases, adsorbents and refining agents and other media, so that the gases and solid oxide inclusions will interact with these media, so as to remove the gas and inclusions in the melt.

The adsorption purification method mainly includes three methods: blowing method, filtration method and flux refining method.

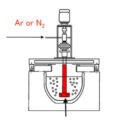

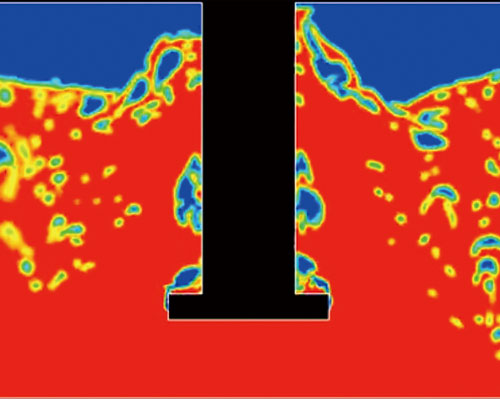

Blowing method started in the 1970s and is an aluminum melt purification process with very obvious hydrogen removal effect. The basic principle is: passing inert gases such as nitrogen and argon into the aluminum alloy melt, causing a large number of bubbles to form inside the aluminum alloy melt, resulting in a hydrogen pressure difference at the interface between the inert gas bubbles and the aluminum alloy solution, forcing the melt The hydrogen in the gas continuously diffuses into the inert gas bubbles and is carried out of the liquid surface together with the inert gas bubbles to achieve the purpose of hydrogen removal.

A large number of research results have shown that inclusions and air are interdependent, and the inclusions are removed at the same time as the air is removed. A large number of experimental results show that this method not only removes the hydrogen in the melt, but also helps to remove the inclusions in the aluminum alloy. It can be seen that this method has a good effect on melt purification. With the rapid development of hydrogen removal technology, online degassing purification equipment has appeared, and the hydrogen removal effect of this process is very obvious.

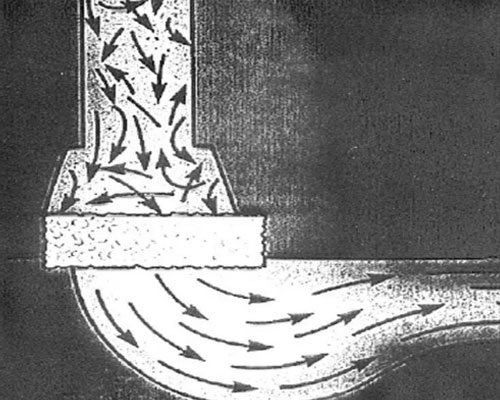

Filtering method uses a neutral or active material manufacturer to filter and separate the solid inclusions in the passing aluminum alloy melt to achieve a process for purifying the aluminum melt.

The filter material mainly uses glass cloth, corundum balls and foam ceramics. Among them, the glass cloth filtration method has strong adaptability, simple and convenient operation, and low cost, but its filtration effect is unstable. The foam ceramic filtration method is characterized by convenient operation and good effect.

The principle of the flux refining method is to add flux to the aluminum alloy melt to cause a series of physical and chemical effects to achieve the purpose of degassing and impurity removal. Because the adsorption and dissolution of oxidized inclusions in the aluminum alloy melt and the chemical interaction between them determine the impurity removal effect of the flux, it is easy to increase the smelting cost and the probability of impurities introduced by human factors. With the rapid development of aluminum alloy melt purification technology, more advanced melt pricessing fluxes, such as granular fluxes, have emerged one after another, which can significantly improve the hydrogen removal effect.

The melt adsorption purification method has been applied in the direct casting and rolling of electrolytic aluminum liquid, and the melt purification treatment process has been used in the production of aluminum alloys at home and abroad to a certain extent.