Casting Ceramic Foam Filter can effectively remove or reduce the inclusions in the molten metal, improve the purity of the molten metal, and make the surface of the molten metal casting smooth. Our ceramic foam filter uses good portiforium foam and high purity ceramic as raw material, can remove non-metal solid mixture from molten aluminium and aluminium alloy effectively in your aluminium casting industry.

Ceramic foam filter molten metal filtration is suitable for casting aluminum rods, aluminum ingots, aluminum plates, and other aluminum alloys.

Since the ceramic foam filter is used in the casting process to filter the solid slag contained in the molten metal such as metal oxides, thereby improving the quality and yield of aluminum alloy. Therefore, the use of ceramic foam filters promotes the technological progress of the foundry industry.

Ceramic foam filters can filter out the source of pollution generated in the aluminum casting process.

On the one hand, during the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state. It is prone to oxidation, reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag (such as furnace lining fragments, flux Chlorides, carbides, etc.) and coarse intermetallic particles, etc.

These impurities often cause bubbles and inclusions in the casting billet, which seriously affect the purity of the molten metal, thereby further affecting the processing performance, mechanical properties, corrosion resistance, and the appearance quality of the product.

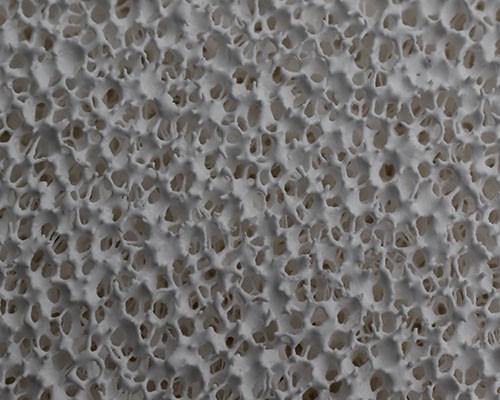

Ceramic foam filter for aluminum filtration has a network hole-like structure, which has a certain strength and can withstand the pressure difference of the metal liquid level and the impact of the metal flow. Because this material has a precise structure, uniform quality, and a large surface area, the filtering effect is excellent.

AdTech specially designed Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications.