How to improve the quality of the molten aluminum and effectively remove the inclusions such as hydrogen and aluminum oxide, the key is the refining process.

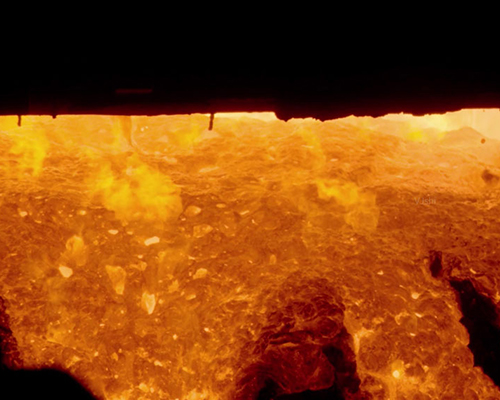

Due to its non-toxic, odorless, light-shielding, moisture-proof, corrosion-resistant, light material, high barrier properties, UV resistance, easy to bend during deep processing and utilization, excellent adhesion and heat sealability, and good surface printing performance. It is widely used in cigarette, medicine, food, electronics, daily chemical, and other industries. During use, the thickness of double zero aluminum foil reaches double zero five and double zero six, or even thinner. Therefore, the mechanical properties and pinhole degree of double zero aluminum foil have higher requirements. However, during the smelting process of molten aluminum, due to the presence of inclusions such as hydrogen and aluminum oxide, the double zero aluminum foil often fails to meet the required performance, and even produces waste products, which seriously affects the company’s economic benefits.

The methods of refining molten aluminum can be divided into two categories:

One is the adsorption method, mainly through the contact between the adsorbent and the melt, so that the adsorbent and the impurities in the melt have physical, chemical, physical or mechanical interactions, so as to achieve the purpose of hydrogen and impurity removal.

The second is the non-adsorption method, which changes the equilibrium state of the metal, gas, and inclusion system through physical effects such as vacuum, ultrasound, and density difference, so as to separate the gas and impurities in the molten aluminum. Although the vacuum treatment method has its own advantages, the equipment is expensive and costly, and it has not been widely used.

In the actual production process, the non-adsorption method is rarely used, and it mainly focuses on laboratory theoretical research. In recent years, ultrasonic treatment and electromagnetic purification technology has become a hot spot in the study of melt purification. In the smelting process, the most widely used is the adsorption method. The adsorption method includes two categories: the CFF filtration method and the floatation method. Because the floatation method is relatively simple to operate and does not produce secondary hazards, it is the most widely used refining technology.