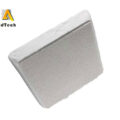

The foundries foam ceramic filter can remove impurities in the liquid aluminum, which can significantly improve the quality of the ingot and reduce the waste rate. The ceramic foam filter materials have been widely used in the metallurgical industry.

The solid non-metallic particles suspended in the molten metal can cause serious difficulties in the aluminum casting and manufacturing process. Ceramic Foam Filters are particularly effective and long-lasting liquid aluminum filters for filtering oxide and non-oxide impurities.

The application of ceramic foam filter plates has become popular in the aluminum processing industry. It is installed in the filter box between the aluminum alloy melting furnace and the casting equipment. When the aluminum liquid passes through the filter plate, the larger impurity particles are intercepted, so as to achieve the effect of purifying the aluminum liquid. The selection of the filter plate depends on the flow rate per unit time and the total amount of aluminum melt. The choice of the ceramic foam filter plate size depends on the cleanliness requirements of the final aluminum melt. The higher the requirement for the cleanliness of the aluminum melt, the smaller the selected pore size.

Foundries ceramic filter molten metal filtration is the last process of aluminum melt purification.

The ceramic foam filter mechanism is generally described as sieving, sedimentation, and deep bed filtration.

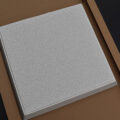

Through mechanical filtration, its filtration efficiency is proportional to the mesh aperture of the foam ceramic. The smaller the mesh, the stronger the interception of small particles.

Filter cake layer effect. With the deposition of particles in the melt, the filter’s ability to capture impurity particles is improved.

Under the same prerequisites, the new ceramic foam filter plate has a high removal rate of impurities in the aluminum melt, and the static pressure difference before and after filtration changes significantly with time. Of course, the smaller the ceramic foam holes, the better the aluminum melt filtration accuracy.