Foam ceramic plate filtering is the last process in the purification treatment of aluminum melt. It is particularly important to choose the second generation of foam ceramic filter plates. It needs to be particularly pointed out that the secondary pollution of the melt that may occur after the aluminum melt leaves the filter box to solidify and form. In this process, use long-life, high-strength, non-stick aluminum, good thermal insulation launders, front boxes, distribution plates, and hot top caps, and eliminate possible pollution sources in time to ensure the cleanliness of the aluminum melt.

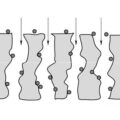

The mechanism of foam ceramic plate filtering and purifying aluminum melt is generally described as diffusion interception and inertial collision interception or screening mechanism, sedimentation layer, and deep bed filtration mechanism. The process of filtering and purifying molten aluminum by foam ceramic filter plates is very complicated, which is a complex process of high temperature physical chemistry and metallurgical kinetics.

(1) Through mechanical filtration such as screening collision interception, diffusion interception, friction, settlement, etc., the filtration efficiency is proportional to the mesh aperture of the foam ceramic board. The smaller the mesh, the stronger the ability to intercept small particles.

(2) Sedimentary layer or filter cake layer effect. With the deposition of impurity particles in the melt, the ability of the mesh support wall in the filter plate to capture impurity particles increases.

(3) The rough surface formed by the gaps on the surface of the network bracket increases the interface between the molten aluminum stream and the ceramic surface, and promotes the flow of impurity particles in the molten aluminum stream to be more disordered, which is conducive to the capture and deposition of solid particles. Come down.

(4) Due to the microscopic cracks and pinholes on the surface of the network support body, a fluoride flux with a strong affinity for Al2O3 particles is pre-deposited, which promotes a complete filter cake effect and strong chemical adsorption, so that the ability to trap and retain impurity phase particles More strengthened.

(5) In the metal smelting process, and the temperature field effect of the heat transfer process, the concentration difference of the alloy solute is bound to be formed. The redistribution and integration of the molten metal is also a good alloying process. Some high melting point metal phases and compounds re-aggregate and grow up, and the small impurity phases can be trapped by filtration after they aggregate and grow up. Especially the effect of two-stage filtration is more obvious.