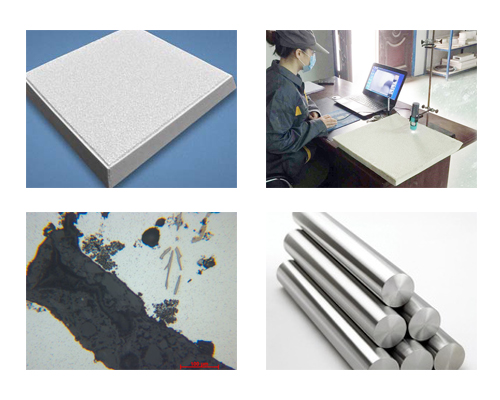

Foam ceramic filter is widely used as the aluminum rod casting filter for many years. The high-performance ceramic foam filter board uses alumina as the main raw material, adds auxiliary ingredients according to the optimized design composition formula, and adopts the organic foam precursor impregnation method, which is mainly used for filtration and purification of aluminum liquid.

In the process of preparing foam ceramics by the organic foam impregnation method, it is necessary to squeeze the excess slurry between the pores of the fully impregnated precursor to form a foam structure. Therefore, the effect of different extrusion methods on the structure and performance of the material is very obvious. The experiment uses a two-wheel-to-roller to carry out the pulping process.

The results of Archimedes’ measurement show that the porosity of the foam has reached more than 90%, and it has achieved the effect of in-situ replacement of organic foam by ceramic materials.

Instructions for Aluminum Rod Casting Filter

Preheat the filter bowl and ceramic foam filter with electricity or air for 15-30 minutes to make the temperature close to molten aluminum. The preheating temperature of the ceramic foam filter should be above 260℃.

The puffed cotton is preheated and sealed. This process enables the ceramic foam filter to be stably fixed in molten aluminum. Preheating will also open the pores of the ceramic foam filter to avoid blockage caused by thermal expansion and contraction.

Check and clean the surface of the filter bowl to keep it clean and intact.

Gently put the filter element into the filter bowl, and press the gasket around the filter element with your hands to prevent the aluminum liquid from flying or floating.

Observe the change in the height of the molten aluminum and maintain the flow rate of the molten aluminum required by the standard. The height of molten aluminum is 100-150mm during normal startup. When the molten aluminum flows, the height drops below 75-100mm, and then slowly increases.

Do not knock or shake the ceramic foam filter when filtering. At the same time, control the flow of aluminum liquid in the washing tank, and it should not be too large or too small.

After filtering, take out the foam ceramic filter in time and clean the filter cartridge.