AdTech provides molten metal baffles to solve the problem of time-consuming and laborious cleaning of impurities such as alumina and calcium oxide in the prior art.

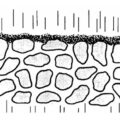

The aluminum liquid flow tank includes a molten aluminum baffle system. The two opposite sides of the settling tank are respectively connected with flow channels for the aluminum liquid to pass through. The bottom of the settling tank is lower than the bottom of the flow channel. The middle of the settling tank is provided with a vertical downward baffle. The bottom is higher than the bottom of the sedimentation tank and lower than the bottom of the runner.

In operation, the fluid rising from the storage tank during the backwash process hits the bottom surface of the runner and is guided to and below some baffles. The flow rate of the fluid circulating under these baffles decreases, causing the air and certain filter media to settle. The fluid circulates under these baffles and is eventually directed away from there. The released air forms an air pocket under these baffles and creates a higher or lower level of fluid under the baffles. If too much air is generated under these baffles, the air will become turbulent, and air and fluid may emerge from under the molten metal baffles, increasing the turbulence. If the amount of air is too small and the liquid level is too high, fluid and media will emerge from the exhaust structure. Therefore, the amount of air discharged from under the baffle can be adjusted by the adjustable discharge device, thereby adjusting the fluid level under the baffle to reduce turbulence and promote the static of the fluid.

The fluid flowing out from below the baffle flows upwards and collides with other baffles parallel to the flow trough, the flow rate is further reduced, and the settling capacity is improved at the same time. The fluid that is substantially free of filter media flows over the upper surface of the launder, thereby entering the launder. The granular medium that settles out of the fluid descends toward the storage tank until it re-enters the flow path circulating under the baffle system structure. Once the backwashing is stopped due to the interruption of the air flow, the medium will settle into the water tank to restore the buoyancy state in the water tank. This structure also allows floating particles to flow into the launder instead of returning to the filter medium of the trough.