Molten aluminum and its alloys degassing refining is an important steps before casting. Degas to reduce hydrogen content. Online degassing is a popular method, it is carried out with the help of SNIF, LARS, and other online degassing refining equipment.

Refine the grain to improve the microstructure of the cast product. It involves adding a grain refiner to the melt before or during casting.

The aluminum melt is in contact with an intimate mixture of inert gas and a sulfur halide compound in gaseous form, and the gas mixture is bubbled through the melt by using a spray gun or other conventional inlet device. The solid debris particles entrained in the melt are brought to the surface, removing the hydrogen, and the melt is effectively degassed in this way.

The aluminum-containing melt to be purified is generally maintained at a conventional degassing temperature of about 1200 degrees Fahrenheit to about 1550 degrees Fahrenheit. Bubbling gas through the melt inherently removes heat energy from the melt, so it can withstand temperature drops of up to 100 degrees Fahrenheit, but preferably less than 50 degrees Fahrenheit, under normal processing conditions. Aluminum and aluminum alloys are purified, and the entrained hydrogen is removed together with the entrained hydrogen in inert gas within an appropriate time until the impurity content is reduced to a preselected level. The resulting scum containing these impurities on the aluminum surface is dry powdery material. When skimmed from the surface, it can enhance the effective removal effect, reduce the scum impurities in the finished casting and minimize the waste of primary aluminum.

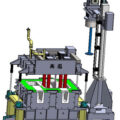

AdTech online degassing equipment mainly processes molten aluminum that contains a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which are removed after being processed by degassing equipment. The efficiency of molten aluminum degassing refining equipment is stable at an average of 60%. When Mg is less than 1% in molten aluminum working with argon, the best degassing effect can reach 0.09cc/100g.