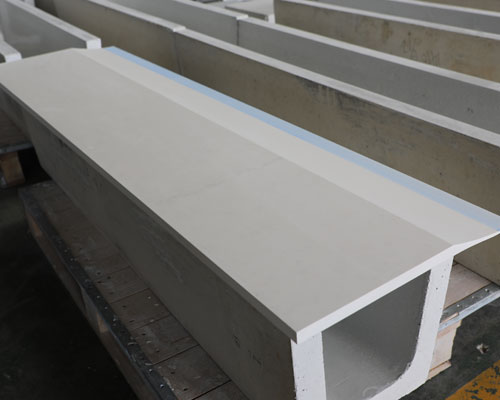

Feed caster tip is used for crystal forming and size control of aluminum strip castings in casting and rolling production lines. It is formed by vacuum suction filtration of high-purity fibrous materials, and processed by sophisticated equipment.

Advantages of Aluminum Strip Casting Feed Caster Tip

- It adopts nano-fiber composite material for integral molding, high-precision equipment processing, precise size control, appropriate density and stiffness.

- The key parts are strengthened by nano-coating, and the surface of the hole is sealed. It has good non-delamination and non-stick performance, which enhances the corrosion resistance of molten aluminum.

- A reasonable symmetrical flow channel is designed in the internal structure to meet the requirements of liquid aluminum fluid mechanics.

- It has good heat preservation and can effectively control the constant parameters of the casting-rolling zone temperature. It is the best choice for casting and rolling high-quality aluminum foil blanks.

- Low deformation, easy to adjust the gap between the nozzle and the roller, improve the surface quality of the aluminum foil blank, and effectively improve the white and dark lines.

What problems do you encounter when casting aluminum strip castings?

The gas in the cavity of the casting nozzle and the nozzle plate cannot be quickly removed after heating. The occurrence of striping defects.

In addition, the accumulation of gas in the internal cavity can cause an explosion during installation. In severe cases, the oxide film will roll up and produce slag streaks, or cause defects in the casting lip, which prevents production.

The surface of the hard material nozzle plate is 23mm, which is the densest layer, so even if the surface is punched, it is helpful for gas collection and diffusion. The hole diameter of the poke hole is 1″ 2mm, which should be evenly distributed on the surface of the nozzle plate. The hole position should not be close to the arc surface.

Before use, please use far infrared drying technology to dry feed caster tip.

Before assembling the Castertip, please use a far-infrared drying oven for drying treatment, which can remove the internal moisture of the Castertip material and greatly reduce the explosion rate of the Castertip caused by the accumulation of water vapor during the installation process.

The far-infrared drying oven has the advantages of good heating effect, high heating efficiency and convenient operation. It is obtained through practical application and collection of mass production data. Castertip processed by far-infrared drying technology has a greatly reduced possibility of gas gathering explosion or tube blockage.