The harmful impurity elements in the molten aluminum can be removed by vacuum treatment and chemically removed by refining flux. Vacuum treatment is to use impurity elements whose boiling point is lower than that of aluminum (boiling point is 1800°C) and the main components of aluminum alloy under vacuum conditions, and remove them by evaporation. Vacuum treatment can reduce the amount of calcium, zinc, etc. to less than 1 ppm, but it has not yet obtained industrial applications.

Harmful impurity elements can chemically react with the refining flux to form compounds that can be separated from aluminum, and are carried into the refining slag and discharged through the adsorption of the refining flux.

The main methods to remove oxide inclusions are: electric flux method, filtration method, and refining flux method. Among them, the research and application of refining flux method and filtration method are relatively extensive and in-depth.

In the aluminum alloy smelting process, the refining flux is added into the melt, and through a series of physical and chemical actions, the effect of removing oxide inclusions is achieved. The impurity removal ability of the refining flux is determined by the adsorption and dissolution of the refining flux on the oxide inclusions in the melt and the chemical effect of the refining flux in the melt. The smaller the interfacial tension between the refining flux and the oxide inclusions, the better the adsorption effect and the stronger the removal of oxide inclusions.

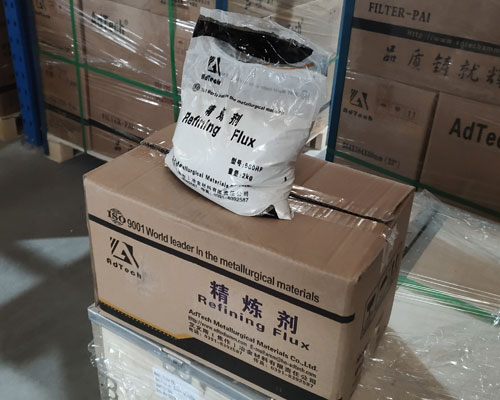

The main components of aluminum alloy refining fluxes are chloride salts, fluoride salts and other compounds. After proper heat treatment and sieving, the particle size is uniform, which is beneficial for the carrier gas (N 2 or under the action of Ar) in the refining tank to uniformly enter the lower layer of molten aluminum through physical and chemical changes.

Molten aluminum forms a large number of small bubbles, which completely contact the molten aluminum to separate liquid aluminum [H] and other harmful gases. Certain substances in molten aluminum refining flux will strongly absorb and melt oxides and suspended matter in the melt and stick to the bubbles. As the bubbles rise, they are brought to the surface of the molten aluminum for the purpose of refining, purifying, degassing and removing slag.

After flux refining, ceramic foam filters are generally used for further filtration, which has the advantages of high efficiency and low cost.