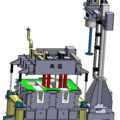

The double rotor degassing unit uses a new type of high silica lining, located between the furnace and the casting machine, and mainly removes hydrogen and other residues in the molten aluminum.

After being purified by the AdTech degassing unit and CFF filter box, the aluminum liquid can be used for the production of high-precision products such as computer hard disks, photoconductor drums of photocopiers, aluminum foil, PS plate base, and turbine engine fan blades.

Double Rotor Degassing Unit Working Principle

- Hydrogen is absorbed into the bubble and is eliminated;

- Alkali metals are eliminated by chemical interaction with chlorine gas (formation of chloride);

- The inclusions are trapped by bubbles and then rise to the surface of the melt to form dross.

Precautions for use degassing unit

- Before baking, twist off the nut around the vent hole of the box to facilitate the drainage of moisture from the insulation lining.

- Before baking, the degassing box raises the rotor, and the filter box cannot be equipped with filter plates.

- The aluminum outlet, the aluminum inlet, the discharge port, and the rotor hole of the box body are plugged with a fiber blanket. The upper mouth of the box body is covered with a 20mm thick fiber blanket and the cover is sealed.

- The thermocouple is inserted into the temperature measuring hole of the box cover to control the temperature of the furnace gas.

- The normal control temperature of molten aluminum in the box is about 750℃, and the temperature difference of furnace gas conduction is about 50℃, so the maximum control temperature of furnace gas during baking is 800℃.

- If the temperature control meter is equipped with a program control function, it can run automatically according to the baking curve setting; however, it can also be controlled manually.

- If the temperature control meter does not have a program control function, it will adopt stepwise manual control in time intervals. The maximum current of the power regulator does not exceed the rated current.

- The highest temperature is 800℃ and the heat preservation is over, the temperature will be naturally cooled down after the power is cut off, and the cover can be opened to cool down or inspected only below 200℃. At the same time, tighten the vent nut.

Note: Do not open the cover or remove the rotor hole, discharge hole, and aluminum fiber blanket during the whole process to avoid cracks in the lining caused by the shock of rapid cold.